About STARK Spannsysteme

STARK Spannsysteme – where technological lead meets mountains.

The economy in Vorarlberg – the westernmost federal state in Austria – is as varied as its landscape. A variety of industries and regional value chains on an international level characterise the economy of this region. In terms of patent applications, Vorarlberg regularly ranks amongst the top five regions in Europe. Due to its economic power, this state is on a par with the metropolitan regions of Paris and Stockholm. The average person from the Vorarlberg region is said to have the qualities of diligence, efficiency, open-mindedness and courage. Performance is valued by the population just as much as creativity and commitment. Vorarlberg is a border area. 80 % of the 350 km long state border is an Austrian national border. The region borders Switzerland, Germany and the Principality of Liechtenstein. This unique four-country location is the main reason for the openness and internationality of the local economy. STARK Spannsysteme is located amidst this remarkable economic region, surrounded by spectacular Alpine scenery.

Equipped for the new tasks

STARK Spannsysteme expanded product groups and invested in extension.

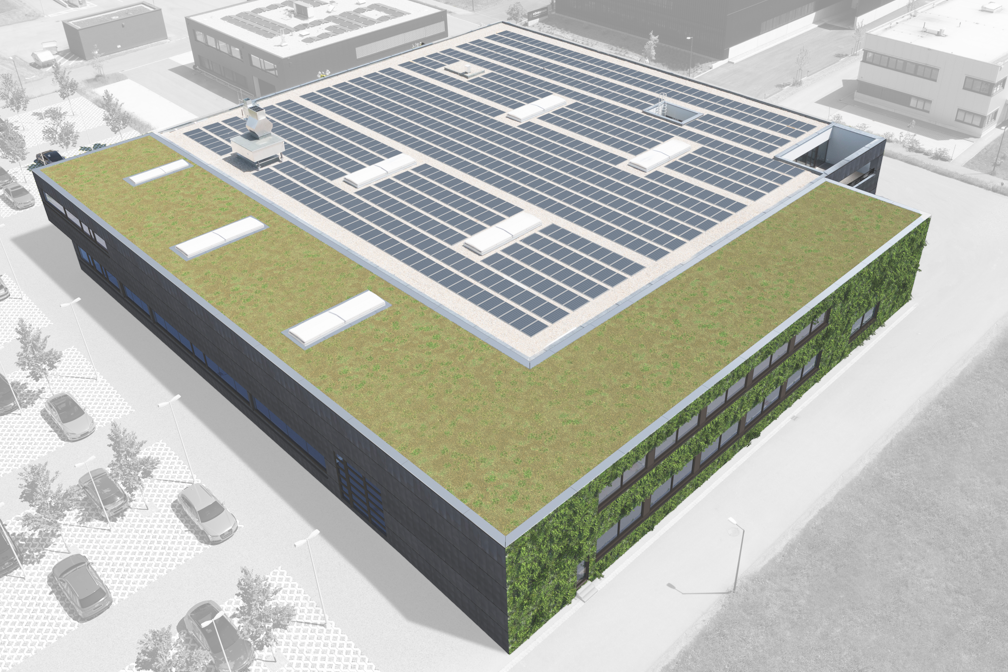

In 2017, STARK moved from Götzis to the Römergrund industrial park in Rankweil. At that time, 6.5 million euros were invested in the new building. In 2021, STARK took over the workpiece clamping systems (HILMA machine vises) within the Roemheld Group and invested in the company location in Rankweil. Construction work began in the summer of 2021 and was completed in the second quarter of 2022. In addition to the extension on its own property, further areas for future extensions could also be secured.

The new production areas were added to the existing building on two sides. In addition, a photovoltaic system and green roof and facade areas were implemented as an ecological contribution in the course of the extension. The costs for the extension were put at around 3.5 million euros. With the takeover of the product group and the new building, the number of employees has also increased.

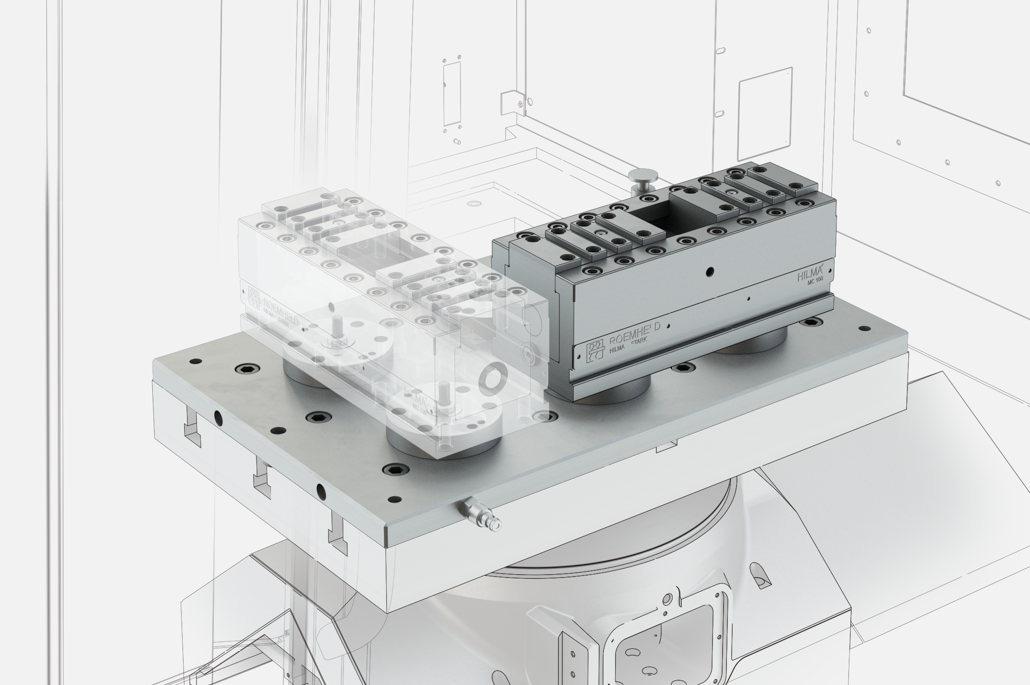

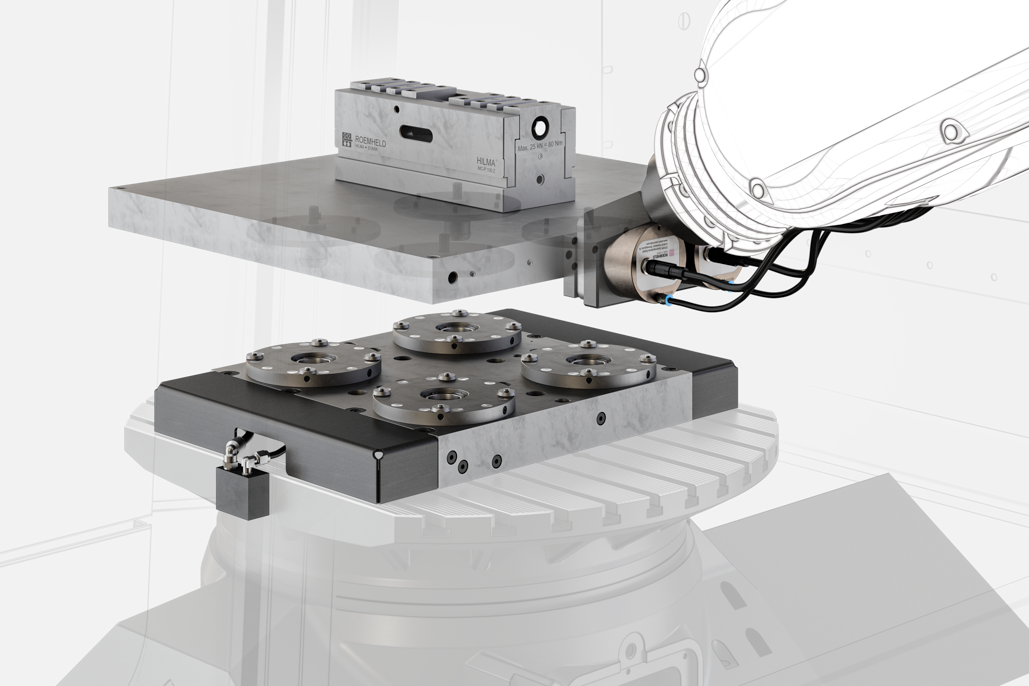

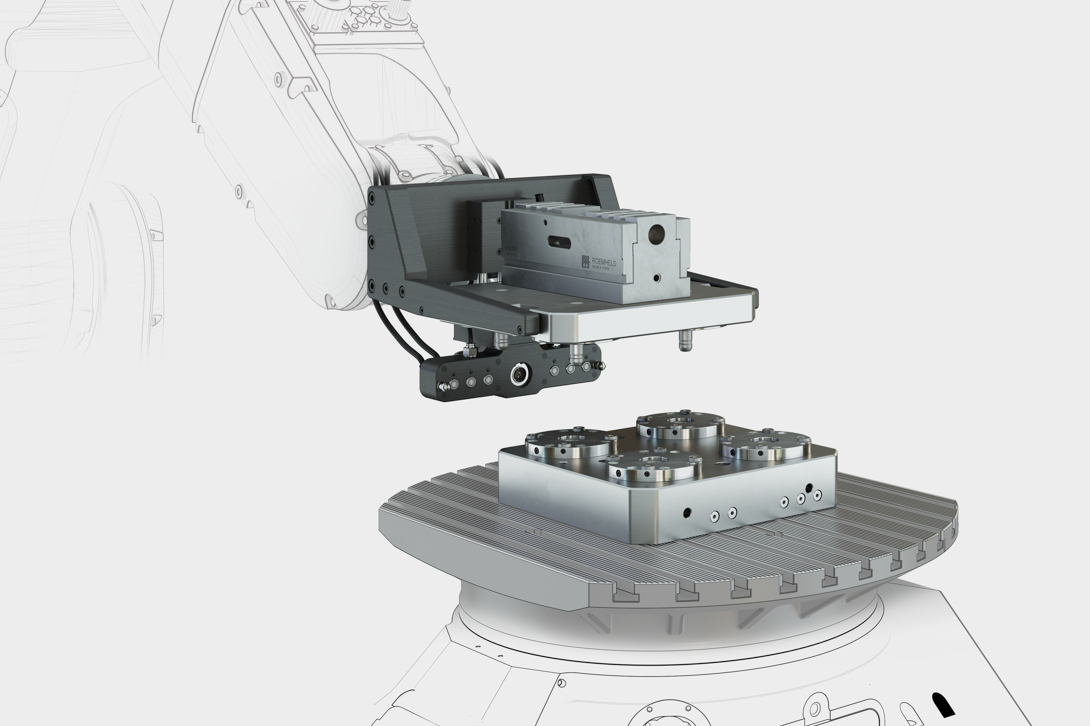

Optimising synergies

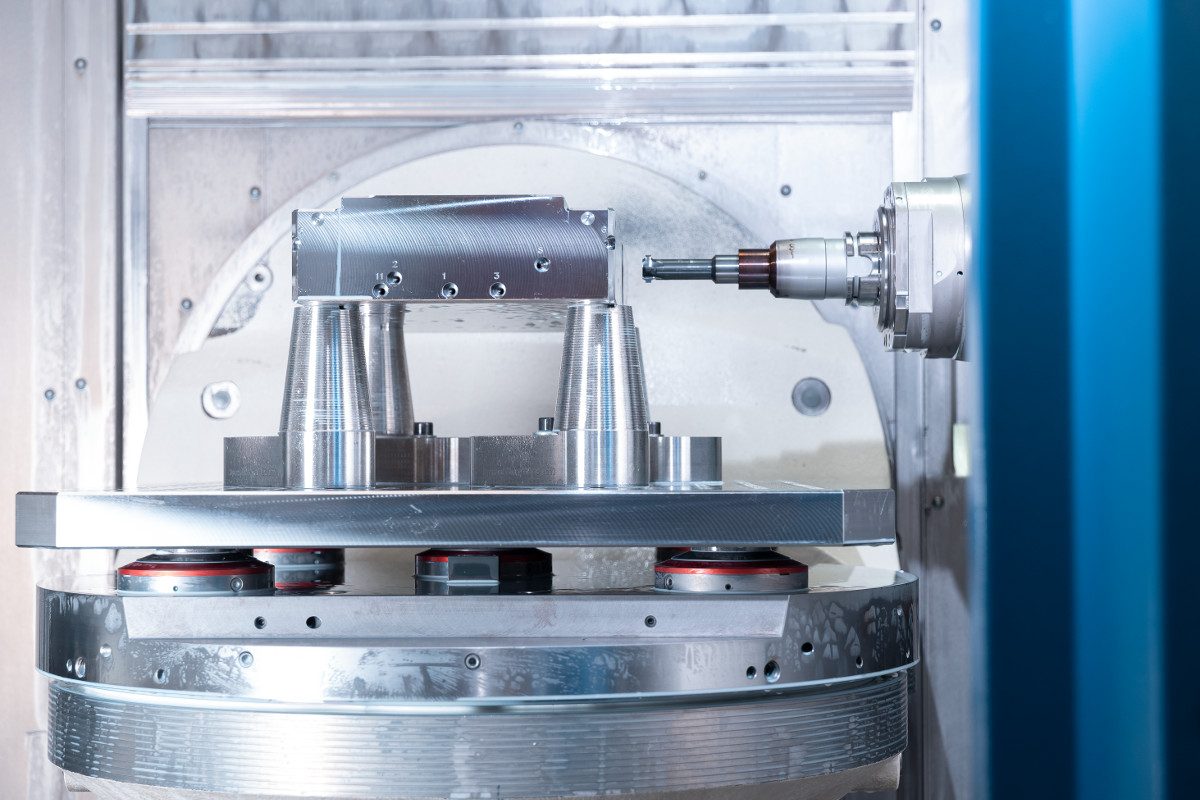

HILMA machine vises can be perfectly complemented and combined with STARK zero point clamping systems.

Facts about the extension

New space for production and administration is being created on a site area of around 1000 m²

- 250 m² administration & social areas

- 500 m² assembly area

- 400 m² basement production area

- 200 m² storage area incl. goods handling area

- 200 kWp PV system on the existing flat roof

- 900 m² green roof area

- 285 m² green façade

Fast availability, accuracy, quality and process reliability

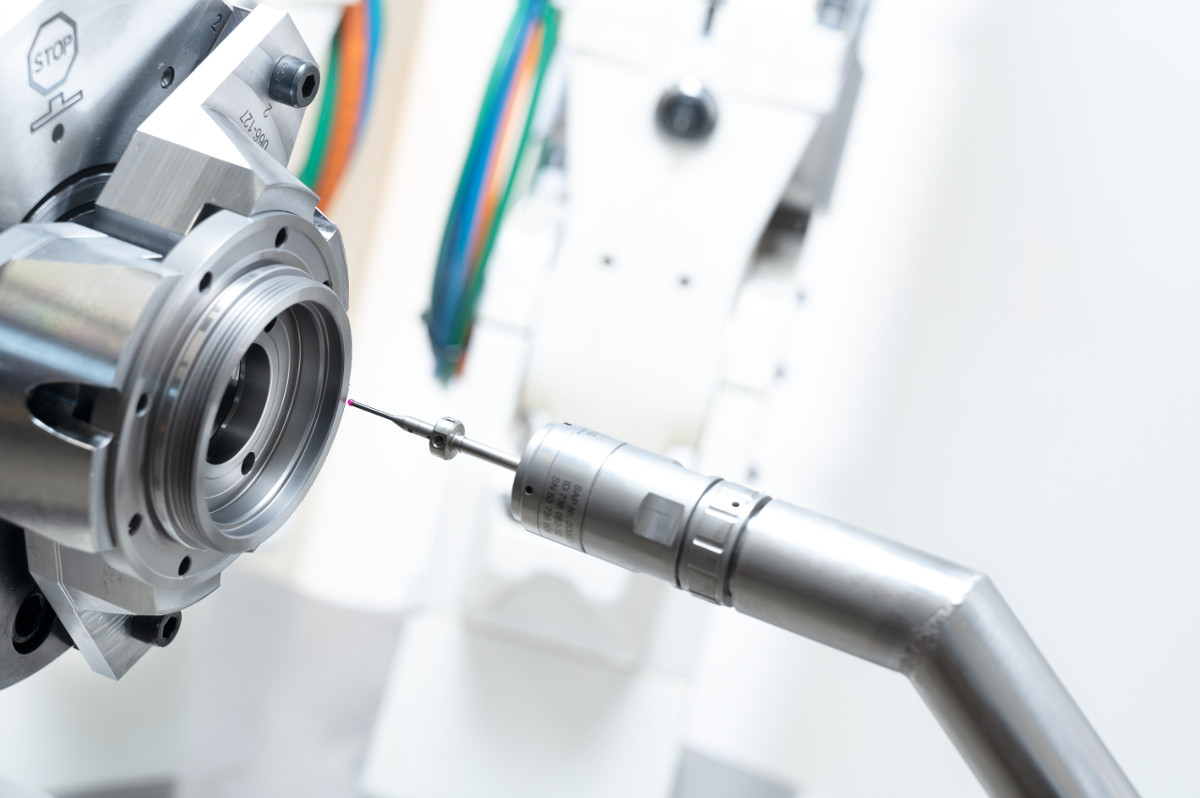

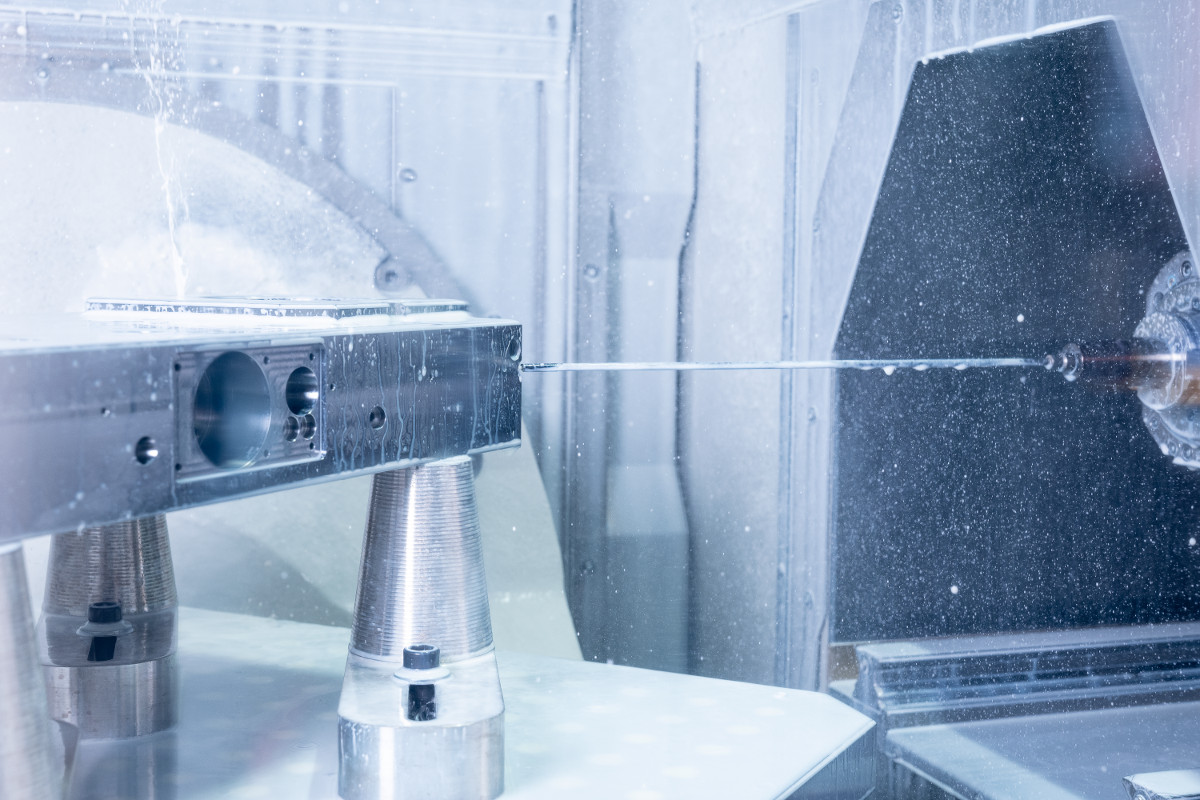

STARK attaches great importance to optimally designed processes – from development and design to production, assembly and quality assurance, the modern business premises offer optimum conditions.

The fully air-conditioned production facility, state-of-the-art machinery, flexible and efficient production structures and highly qualified employees guarantee high-precision STARK product quality, delivery reliability, efficiency and cost transparency.

We strengthen our own competitiveness and that of our customers with a delivery reliability of over 98 %.

Innovative solutions, tried and tested components at a high technical level

Our product quality is based on the highest possible development standards, high-quality materials and state-of-the-art machinery and processing technologies.

Thanks to its decades of history and as a pioneer in zero point clamping technology, STARK has in-depth knowledge of products and applications.

An end-to-end quality assurance and testing system is an integral part of all processes. The vibration-decoupled and shielded measurement equipment and a test system for long-term tests under production conditions guarantee our customers the highest degree of reliability.

STARK stands for quality, excellent products, highly efficient processes and outstanding results

We achieve this by practising common values and striving for common goals. The expertise and commitment of our employees are decisive factors that drive the success of our company.