STARK.intelligence

Digital zero point clamping technology

STARK.intelligence allows for complete digital status recording

A machine table or fast closing plate equipped with the STARK.intelligence sensor system allows transparent and standardised mapping of the status or the process sequence and for maintenance. The clamping status can be directly integrated into the process as digital information. The system also provides valuable information on the health status of the clamping devices and thus allows status-based maintenance.

- Digital status

Clear detection of the piston position (clamped/released) per clamping element — for manual and automatic loading — to support a continuous production process - Individual predictive maintenance

To ensure machine availability - Cost benefit

Through digitalised zero point clamping system - Modular and bus-compatible system

- Easy to integrate into machine table or fast closing plate

- Can be combined with various STARK product families and sizes

- Standardised communication via IO-Link

Raw data access possible

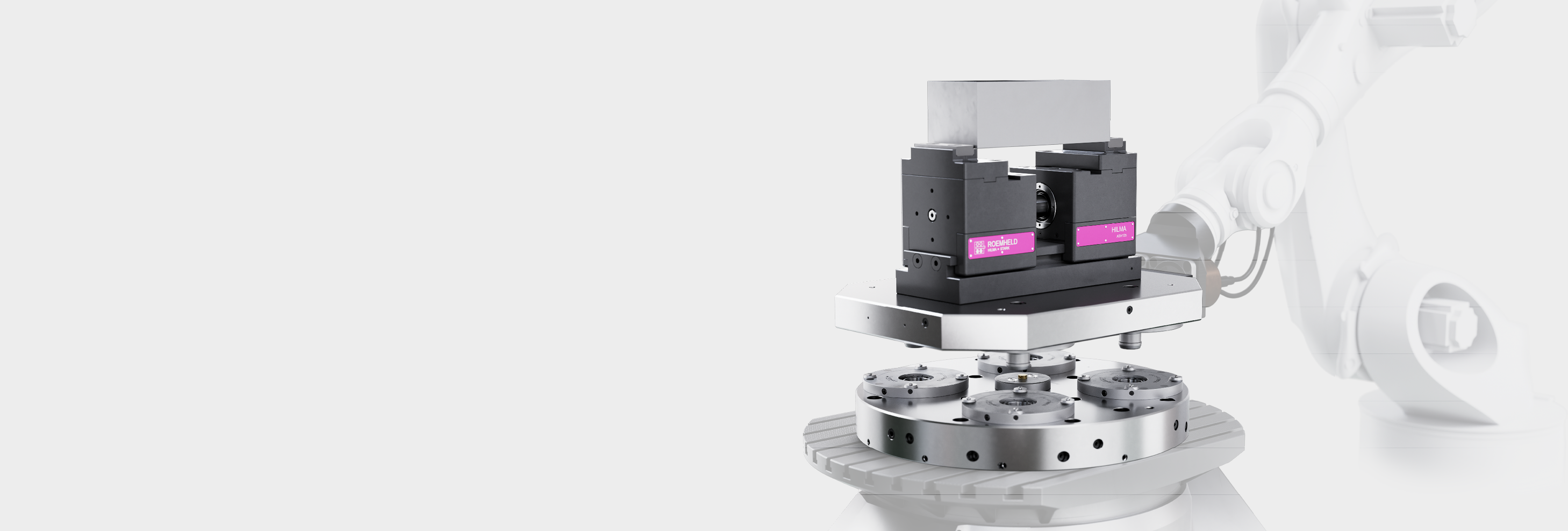

Typical 5-axis milling application with automated loading

- Fast closing plate with 6 clamping elements STARK.classic.NG.2 Twister with sensor boxes

- Master unit with IO-Link standard and inductive coupler

Architecture / Modular system

Digital zero point clamping technology

Each clamping element can be "digitalised" with a sensor box and thus becomes a data source in the STARK.intelligence solution space. The individual data sources (sensor boxes) exchange information with the master unit via simple and robust cabling (internal bus system). The master unit in turn makes the condensed information available via the IO-Link standard (the raw data is also available on demand).

- Depending on the requirements of the application area, the solution can be adapted as a modular system

- Optional integration of an RFID interface (e.g. detection of pallets/workpieces)

- Fixed wiring, inductive coupling, integration in an Ethernet fieldbus, etc.

- Coordinated user interaction, e.g. via dedicated HMI (Human Machine Interface) - The scope of the solution is adapted to the requirements in a modular principle

1. Machine table / zero point clamping system

Regardless of how the machine table or the fast closing plate is designed or which clamping element (design/size) is used, the information flow of the sensory components is standardised and always remains the same.

2. Sensory components

3. Communication options

The communication options and interaction options shown can be adapted as a modular system according to requirements.

4. Interaction options

The solution can be customised for each use case or user group. In this way, only data for integration into a superimposed control system can be offered, or an HMI can be realised as well.

Example of machine visualisation

Digital zero point clamping technology

The example shows one of many ways in which the sensor data can be processed. Depending on the requirements, the data can be individually evaluated via the IO-Link standard.

Description of the example scenario

A choke adjusts and influences the release time of the clamping element.

The release time decreases continuously and triggers a warning as soon as the programmed threshold value is exceeded. Maintenance can be scheduled to avoid possible failure.

User view

SERVICE

- User view limited to essential information

- Clamped system

- Pallet has been detected

- System free of faults

User view

SERVICE

- Released system

- Without pallet

- With attached warning

Supervisor view

SERVICE

- Supervisor view

- Detailed information

- Extended diagnosis

Data flow

Digital zero point clamping technology

STARK.intelligence allows a transparent, scalable and device-independent data flow. By using standard interfaces and protocols, different communication paths can be mapped very easily and supplemented by third-party devices available on the market.

- Different roles have different information needs

- Machine/system operator

- Maintenance/service

- Quality assurance - Standardised interfaces allow different communication channels quite easily

- Visibility of information can thus be adapted or optimised to the respective role