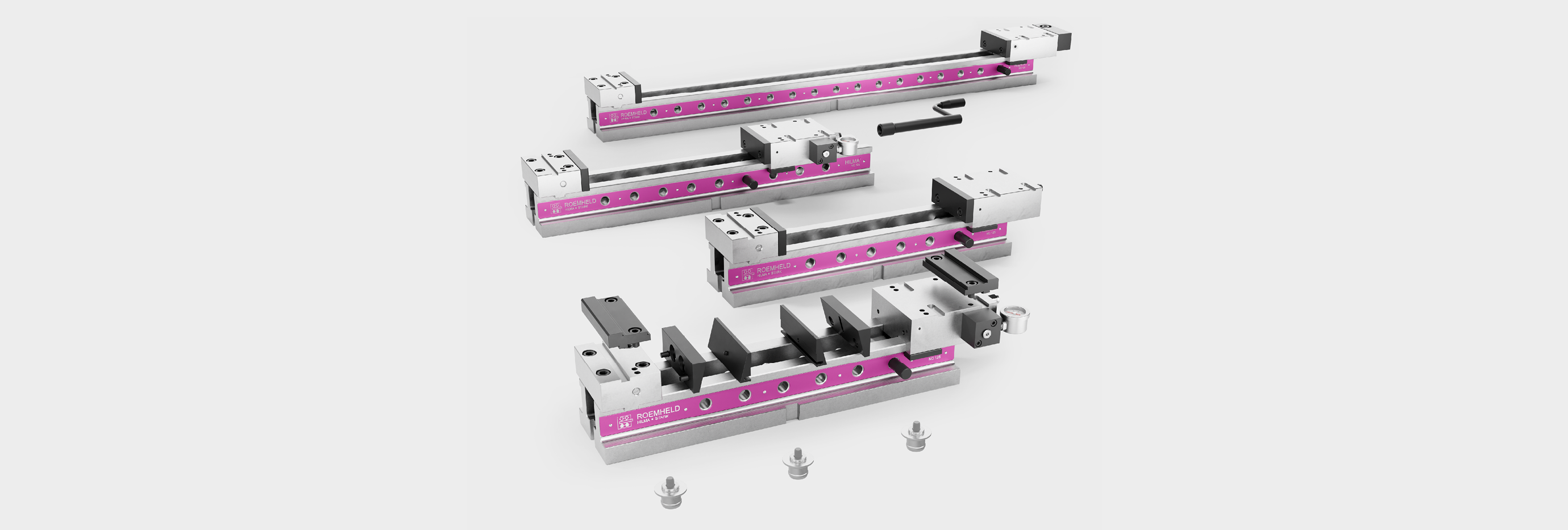

HILMA.MCP

- HILMA.MCP clamping against fixed jaw, mechanically operated, jaw widths: 60, 100 and 125 mm

- HILMA.MCP Z concentric clamping, mechanically or hydraulically operated, jaw widths: 60, 100 and 125 mm

- HILMA.MCP ZB position flexible clamping, mechanically operated, jaw widths: 60, 100 and 125 mm

Application

The workholding systems HILMA.MCP are especially advantageous for 5-axis machining. The compact design allows a good accessibility of the tools to the workpiece. Collision-free tool paths and a 5-sided workpiece machining can be achieved with short standard tools. Due to the good swarf protection, workholding systems HILMA.MCP are particularly suitable for the use in pallet systems. The high force and stability obviate the need for pre-stamping of the workpieces.

Description

Workholding systems of the HILMA.MCP series excel by a very compact design and their patented segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum. Thus, a high rigidity of the workholding system is obtained. The patented segment design ensures a high degree of precision and stability. The guiding clearance is reduced to nearly zero. All essential components are made of hardened steel. The workholding systems of the HILMA.MCP series are already prepared for the use on zero point clamping systems. For this purpose, there are location threads for retractable nipples at the bottom side of the housing.

HILMA.MCP

Advantages

- Patented segment design

- Clamping without deformation of workpieces by position flexible clamping point

- Clamping system also suitable for concentric clamping

- high zero-point stability

- Compact design

- High precision and accuracy of the manufactured workpieces by high rigidity

- Sturdy design and good swarf protection

- Large jaw openings

- Extensive range of jaws

- Clamping of raw and finished parts without retrofitting

- Easy to maintain

HILMA.MCP 125 Z

The mechanical clamping system HILMA.MCP 100 Z concentric, mounted on a rapid change block "Quintus 2": Even complex workpieces are optimally accessible for the 5-side machining, short standard tools can be used without any problems and promise high precision even in complex operations. Tooling costs are reduced. The rapid change block Quintus allows the external setup. The result is less machine down time and increased efficiency of the entire system.

HILMA.MCP 60 H

Two hydraulically operated HILMA.MCPH 60 on a reversible clamping system with workpiece-specific clamping jaws for 4-axis complete machining. The hydraulic lines are directly in the base plates of the HILMA.MCPH 60.

Detailed information

Articles of the HILMA.MCP family on the Roemheld group page

Video

Operating manual

HILMA.MCP clamping against fixed jaw, mechanically operated, jaw widths: 60, 100 and 125 mm

Operating manual

HILMA.MCP Z concentric clamping, mechanically or hydraulically operated, jaw widths: 60, 100 and 125 mm

Operating manual

HILMA.MCP ZB position flexible clamping, mechanically operated, jaw widths: 60, 100 and 125 mm