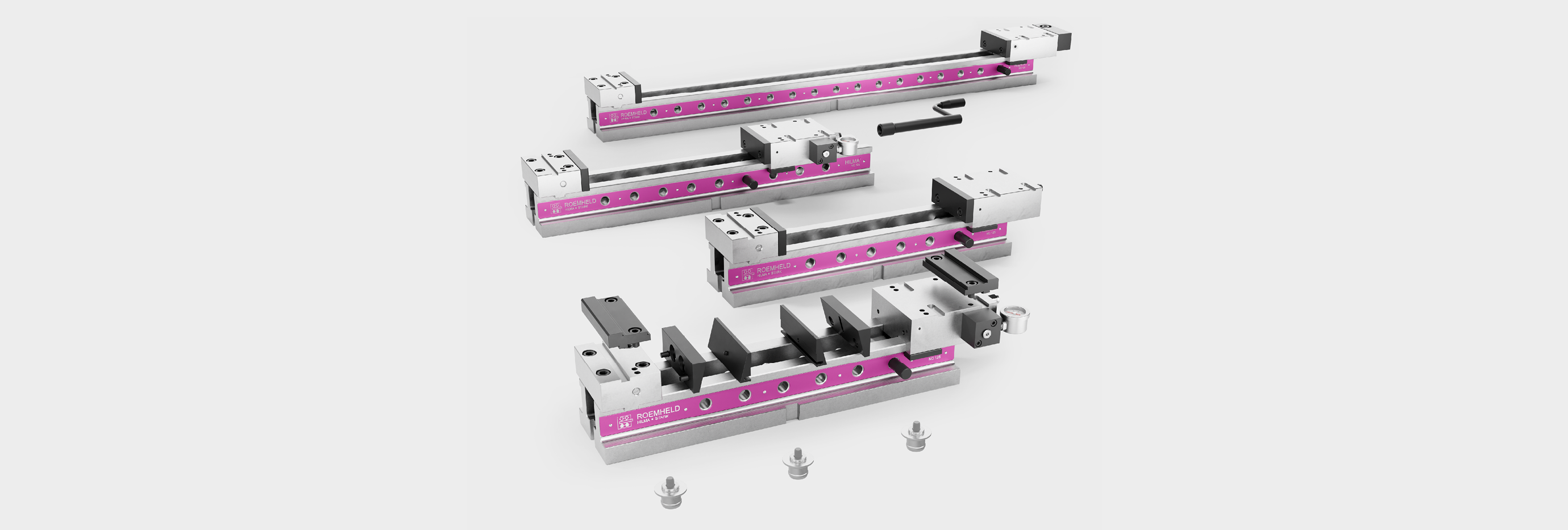

HILMA.MSH Multiple Workholding System

- modular design

- "Premium": highest precision in series

"EasyClamp": for lower-cost introduction

"Goliath": for high demands - jaw widths 24 to 120 mm

The high-precision multiple clamping system HILMA.MSH is modular and can be configured according to the requirement of the machining.

The field of application is in the production of small, medium and large series. HILMA.MSH may be used as an individual system or in combination with additional elements (e.g. towers, bridges, base plates, zero point clamping systems) on all machine tools, machining centres and flexible manufacturing systems.

The simple, well thought-out design guarantees safe and user-friendly handling. The modular design allows any extension to suit specific requirements. Short set-up times, minimum machine travel achieved by high workpieces density, reduced tool changes and a high rate of amortisation, these are the economic advantages of using this system.

Special benefits

- precise, frictional connection between base and clamping module via fine teeth as well as patented eccentric clamping by means of one fixing screw only

- rapid set-up without measuring instruments using the scale on the base module and graduation marks on the fixed and clamping module

- different jaw openings and fix module width from 24 to 100 mm, (60 - 120 mm Goliath) (Linear only 60 mm)

- clamping modules with a rear contact surface accurate in size workpieces need not be accommodated "in mirror image"

- accommodation of a maximum number of workpieces any extension to the base modules is possible

- exact and repetitive accuracy of the workpiece position alignment or zero point adjustment using the machine spindle is not required

Designs

Premium, EasyClamp, Goliath

Premium

highest precision in series

- all faces grounded

- tolerance ± 0.01 mm

- all system parts hardened and corrosion-resistant

- clamping modules with retaining guide

- scale on both sides

EasyClamp

for lower-cost introduction

- all surfaces fine milled and surface hardened

- tolerance ± 0.03 mm

- scale one-sided

- eccentric lead screw with hexagon socket

Goliath

for high demands

- clamping and fixed modules for high requirements up to width of 120 mm

- clamping forces up to 40 kN per element

- additional force absorption with link blocks

Detailed information

Articles of the HILMA.MSH family on the Roemheld group page