STARK.metec

Mechanical zero point clamping system

The STARK.metec product family consists of three robust mechanical zero point clamping systems with high retention force,

12 kN / 20 kN / 50 kN. STARK.metec is a solid, mechanical zero point clamping system that enables simple and cost-effective zero point clamping solutions.

Special features of the STARK.metec product family:

- Simple: quickly installed

- Robust: few individual parts

- Compact: high force density

- Economical: easy maintenance

- Fast: a torque wrench is sufficient

Detailed information on the STARK.metec product family can be found in the catalogue download:

Benefits & Advantages

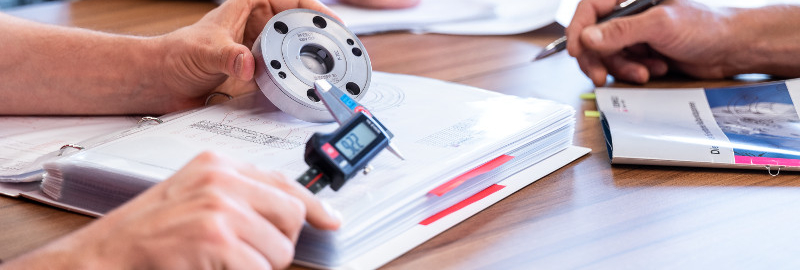

Tried and tested technology with system – original down to the smallest detail

The STARK.metec product family consists of three robust mechanical zero point clamping systems with high retention force:

- STARK.metec.1 with 12 kN

- STARK.metec.2 with 20 kN

- STARK.metec.3 with 50 kN

STARK.metec is a solid, mechanical zero point clamping system that enables simple and cost-effective zero point clamping solutions.

Optimise set-up times and increase flexibility

- Easy to handle – a torque wrench is sufficient

- No media (compressed air, hydraulics) required

- Low set-up times due to short operating times

- No one-sided transverse forces on the retractable nipple during the clamping process

- Simple and robust construction with a long service life

- Low acquisition costs, fast amortisation

Many areas of application

- Universal applicability as a construction element

- Workpiece clamping using vices or other clamping devices

- Direct mounting in your own workpiece holders such as brackets, cubes or plates

- Workpiece direct clamping

- Retractable nipple

- Guide screw

- Actuation of the spindle

- Wedge bolts

- Installation housing

Functions - STARK.metec

Mechanical zero point clamping system

The workpiece is clamped with approx. 2 – 3 turns!

- Workpiece/nipple pallet (1) is clamped/released with approx. 2 - 3 turns on the spindle (6)

- Guide screw (3) fixes the installed STARK.metec in fast closing plate / installation housing (4)

- Wedge bolts (5) clamp retractable nipple (2) precisely to zero point

- Workpiece / nipple pallet

- Retractable nipple

- Guide screw

- Fast closing plate / installation housing

- Wedge bolts

- Actuation of the spindle

Functional video - STARK.metec

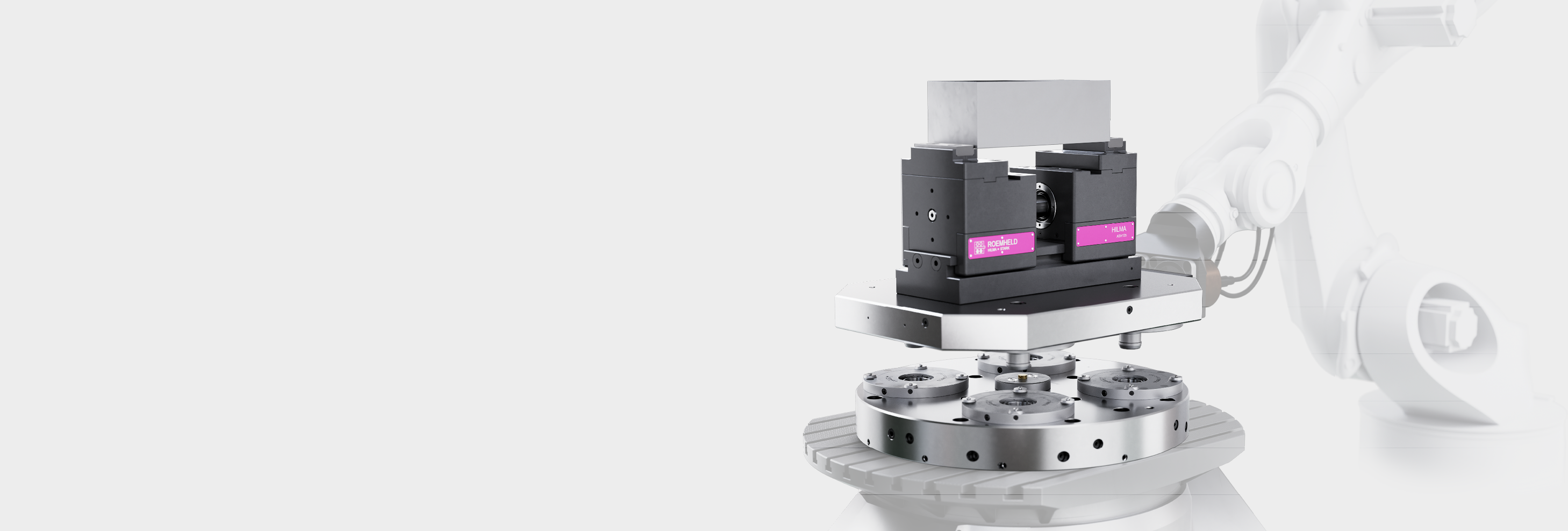

Application examples - STARK.metec

Typical application for milling machines

- Zero point clamping system with two STARK.metec.2 elements (S2000-101)

- The suitable spindle extension allows flexible handling and prevents dirt from penetrating the bore

- No media (pneumatic / hydraulic) are required for the clamping process – a wrench is sufficient

- The system is ideally suited for direct workpiece clamping

(e.g. in tool & mould making)

STARK.metec spindle extension

The spindle extension makes it possible to easily operate deeper recessed STARK.metec. Contamination in the bore can also be effectively prevented with this.

- Flexible handling due to adapted spindle extensions

- Reliably prevents dirt from entering the bore (particularly suitable for assembly in the centre of the fast closing clamp plate)

Application example STARK.metec.1

Easy handling and quick retrofit with STARK.metec

With the solid STARK.metec, you can set up easily and with zero-point accuracy. Due to the purely mechanical operation, machine vices, workpieces or even devices can be changed easily, quickly and cleanly.

Benefits that are worthwhile

- High level of clamping safety

- No media (pneumatics / hydraulics) are required for the clamping process – a wrench is sufficient

- Clamp and loosen with approx. 2 - 3 turns on the spindle (right-hand / left-hand thread).

- High retention forces with low tightening torque on the spindle

- Low installation costs, fast amortisation

Application example STARK.metec.2

Retrofitting made easy with STARK.metec

Set-up costs are the main cost drivers in one-off production and varying series production. With the STARK.metec mechanical zero point clamping system, ongoing series production can be interrupted simply. Changing the device, pallet or just the machine vise is done with zero-point accuracy in just a few minutes.

With STARK.metec, alignment processes of the machine vices are completely eliminated. Positioning and clamping easily with approx. 2 - 3 turns and with a retention force of up to 50 kN.

- Time saving due to minimum set-up times

- Throughput increase

- Competitive advantages due to maximum flexibility

- Optimum reproducibility

Application example STARK.metec

Quick and easy assembly of the machine vise with STARK.metec

With a retention force of up to 50 kN per clamping position, the STARK.metec is ideal for 5-sided machining.

STARK.metec surface-mounted housing

Do you want to gain height?

STARK.metec zero point clamping systems are also available with surface-mounted housing.

As the practical example shows, the elements of the STARK.metec product family can also be integrated very well into self-made structures.

- STARK.metec retractable nipple

- STARK.metec element

- Surface-mounted housing

- Fixing screws for surface-mounted housing/base plate

- Workpiece

- Surface-mounted housing with STARK.metec

- Base plate