STARK.connect

Single and double acting, pneumatic

The STARK.connect series consists of fast closing clamps made of high-quality tool steel and housings made of anodised, high-strength aluminium with very small space requirements due to compact external dimensions. The system is mechanically tensioned with springs, pneumatically powerenhanced and also pneumatically released. The integrated spring assembly makes the STARK.connect self-locking.

Special features of the STARK.connect product family:

- Process-reliable: Industry 4.0 ready

- Flexible: various equalising options

- Ideal: active insertion despite small design

- Robust: high level of resilience

- Fast: very short clamping/release time

Detailed information on the STARK.connect product family can be found in the catalogue download:

Catalogue STARK.connect

The products of the STARK.connect series are fast closing clamps made of high-quality tool steel and housings made of anodised, high-strength aluminium with very small space requirements due to compact external dimensions. The system is mechanically tensioned with springs, pneumatically power-enhanced and pneumatically released. The integrated spring assembly makes the STARK.connect self-locking.

Optionally, this function can also be pneumatically double-acting, which allows even higher values to be achieved.

The STARK.connect.LK versions (element with LOCK function) also have an integrated lock. As a result, higher insertion or clamping forces are achieved even in a depressurised state.

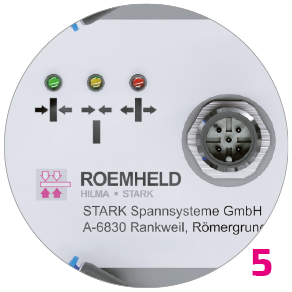

The integrated querying unit detects and signals the clamping state using three/five signals (clamped, released, incorrectly clamped, additionally locked/unlocked for the STARK.connect.LK versions) via LEDs directly on the rear of the element and digitally for transmission to a higher-level control system. The query is designed to be fail-safe and suitable for use in welding systems.

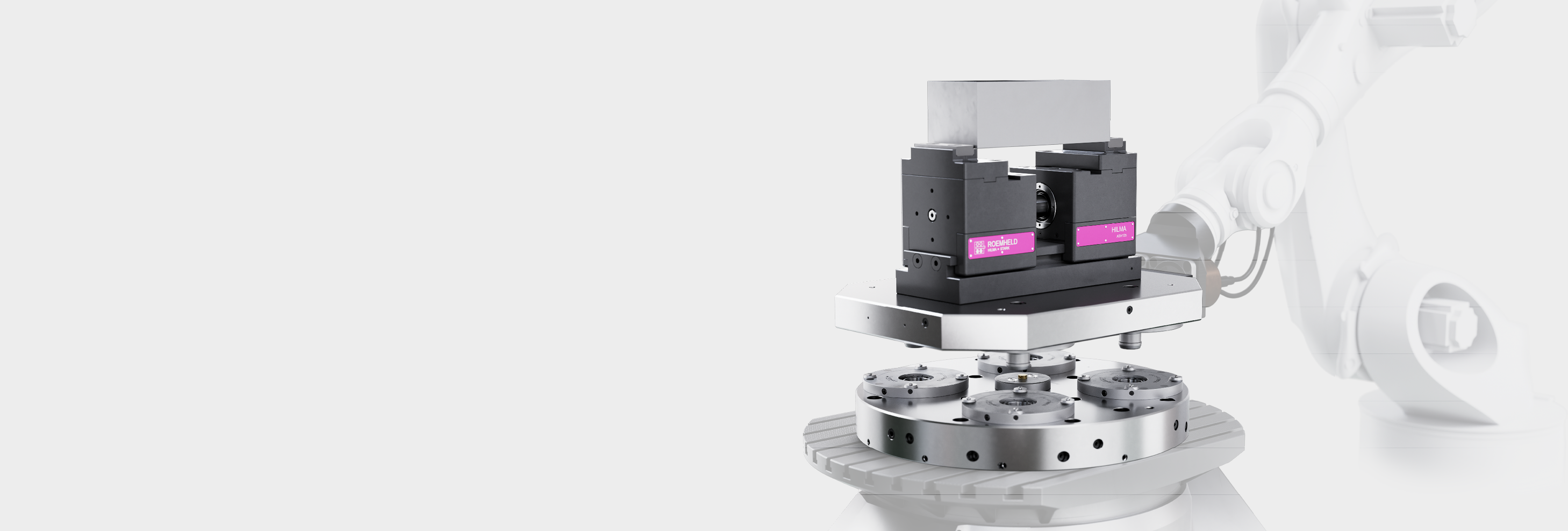

The product series is designed for installation in systems for vehicle shell construction, assembly systems and for connecting machine elements. It is suitable for use in welding environments (weld-proof). Depending on the required accuracies, it can also be used for all common machining processes such as milling, grinding as well as on test benches and assembly devices. Ideal for automatic loading.

Tried and tested technology with system – original down to the smallest detail

1. Design

- Compact design with high clamping forces

- Pneumatic double-acting system with clamping force support

- Simple installation contour

- Easy to maintain – simple installation and cleaning

- Made of high-quality, stainless materials

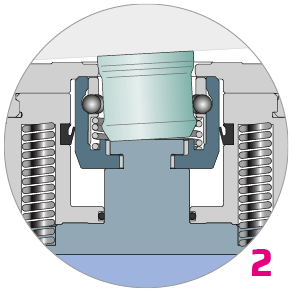

2. Floating support

- Clamping mechanism can move sideways (e.g. temperature variation)

- Inclined entry and exit possible

- Optimal for automated applications

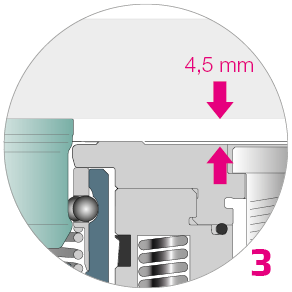

3. Active insertion & optional lifting

- Active insertion force for optimum flat support

- Maximum catch range with 4.5 mm travel

- Vibrations are damped and the quality of the workpieces is thus increased

- Easy robot feeding and removal

- Flexible handling with and without lifting of 1.5 mm from the fit

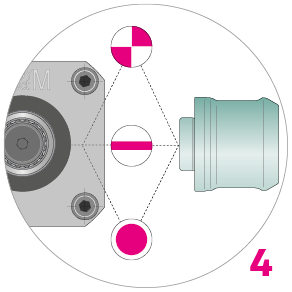

4. Flexible equalising options

- Equalising possible via fast closing clamp or retractable nipple

> Tolerance range with retractable nipple AG ± 0.05 mm / OZ ± 0.2 mm

> Tolerance range with fast closing clamp ± 0.75 mm - Flexible option to compensate for tolerances due to material mix, temperature variation or large designs

5. Fully integrated sensors

- Unambiguous recording of the clamping state

- Direct rear signalling via LEDs

- Digital outputs for simple further processing in the higher-level control system

- High level of robustness and usability in welding environments

Single and double acting, pneumatic

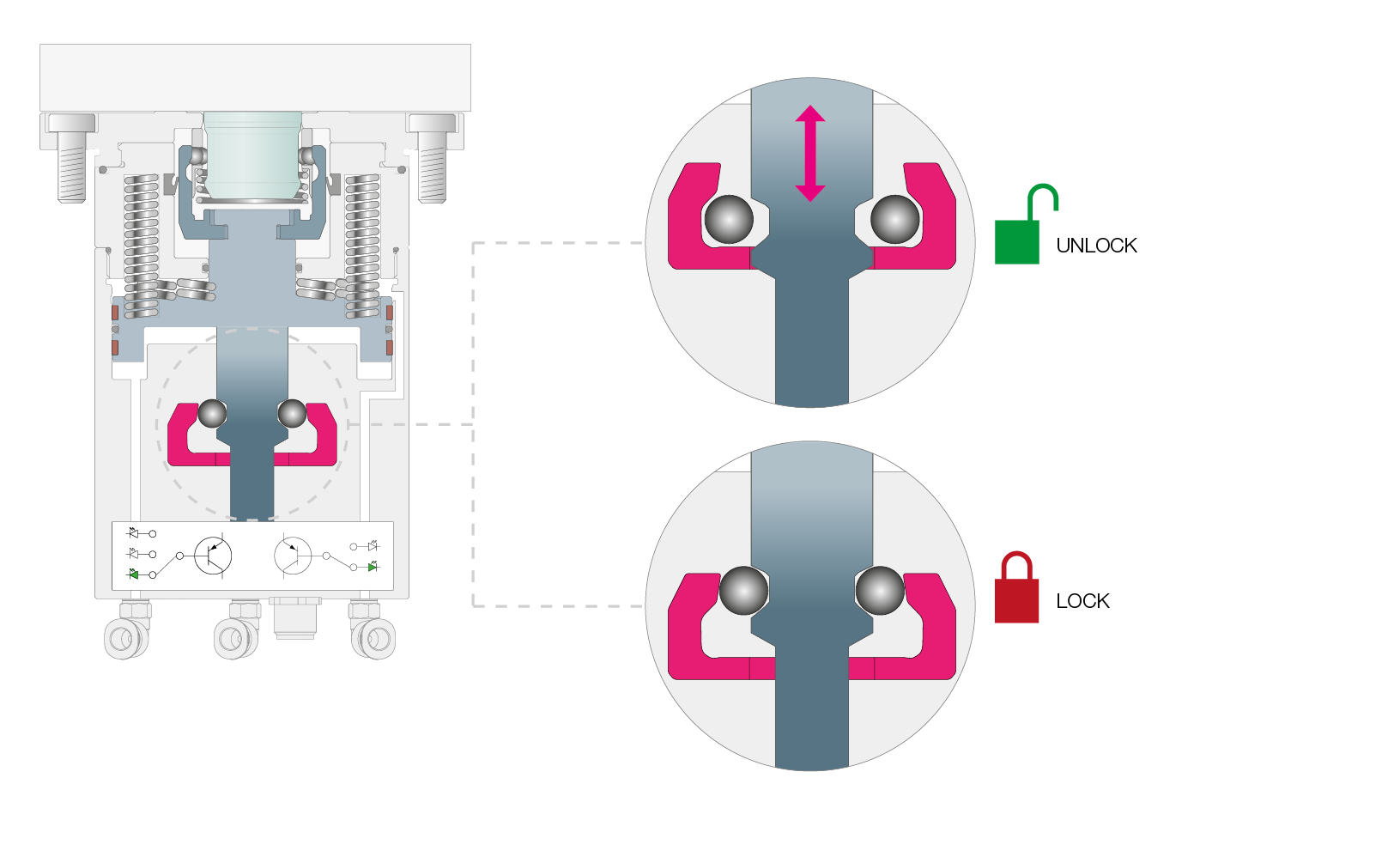

STARK.connect is a pneumatically operated zero point clamping system.

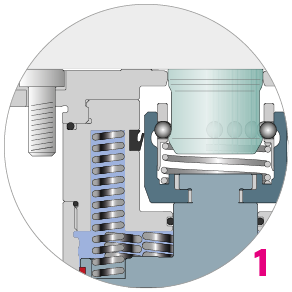

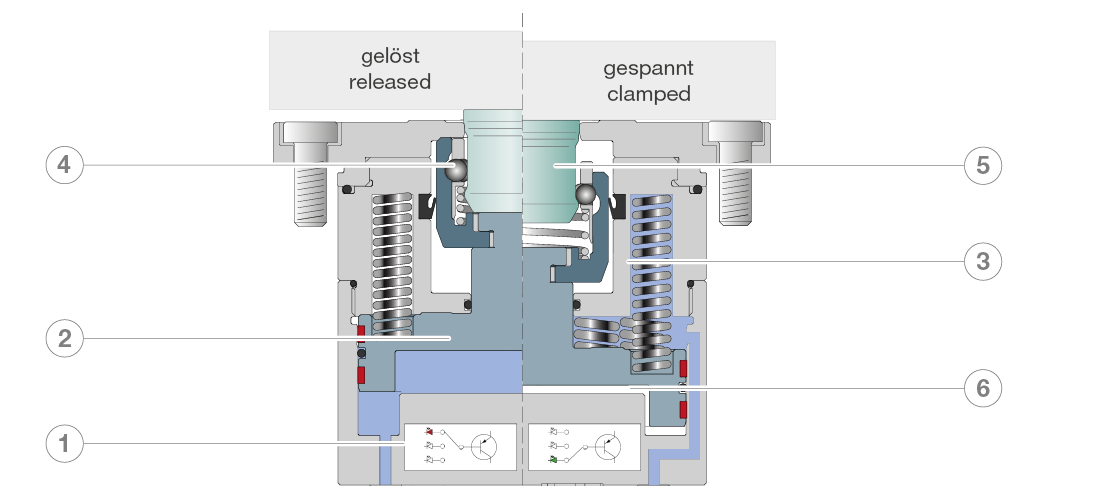

A piston is held in the clamping position by springs. The piston has a double-acting pneumatic design.

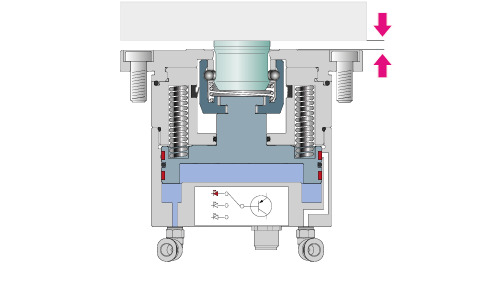

Release:

- The piston (2) is subjected to the release pressure (1) and moves upwards.

The springs (3) are compressed. - The balls (4) move to the parking position.

- The retractable nipple (5) is lifted – "released" signal.

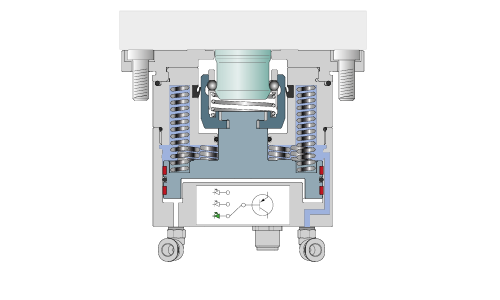

Clamp:

- The release pressure (1) is relieved and drops to 0 bar.

- The spring pre-tensioning force is initiated via the piston (2), which moves down.

- The balls (4) are pressed inwards by the clamping contour, enclose the retractable nipple (5) and pull it on the flat support – "clamped with retractable nipple" signal.

- If there is no retractable nipple in the insertion mechanism, the piston (2) moves to the stop position – "clamped without retractable nipple" signal.

- The piston (2) can be additionally subjected to clamping pressure (6), thus increasing the insertion force.

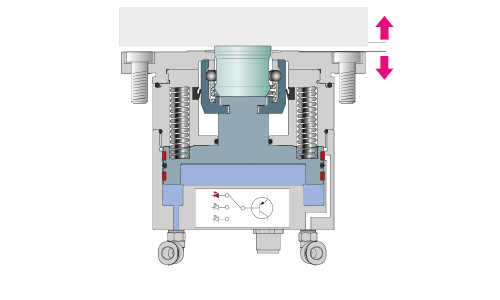

LOCK function with integrated lock

Elements with LOCK function have an integrated lock with a locking force of 10 kN. The LOCK function achieves high clamping forces in addition to the insertion force in the unpressurized state.