STARK.basic

Pneumatic single acting

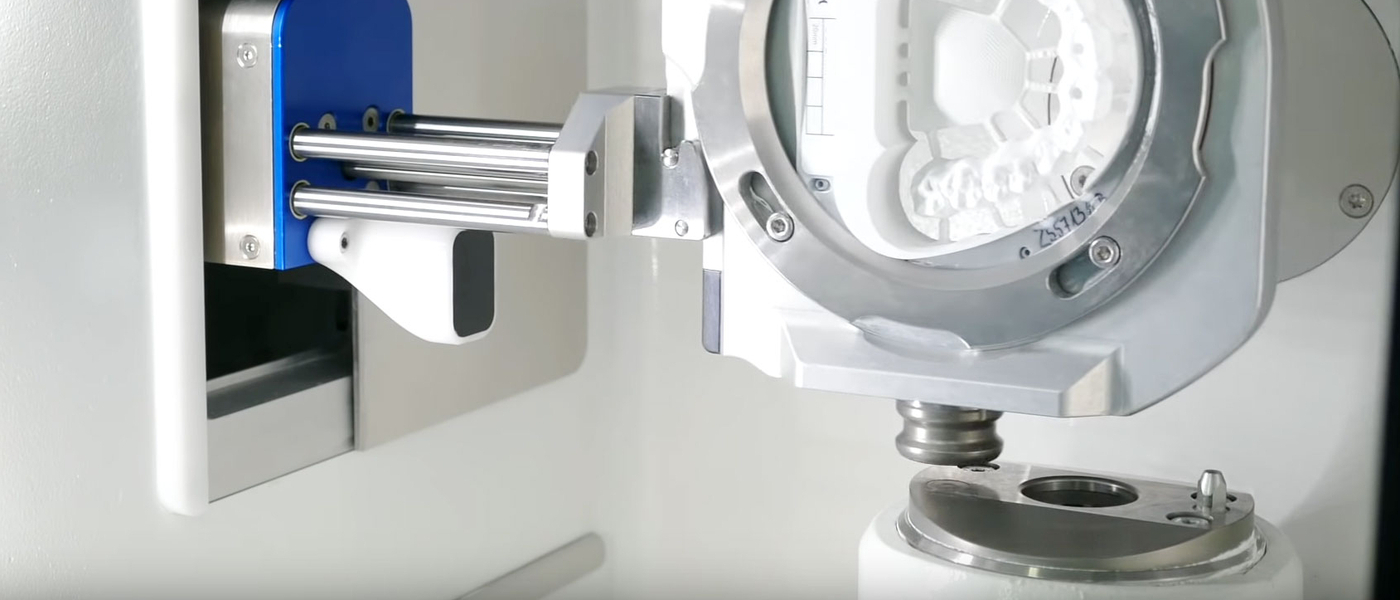

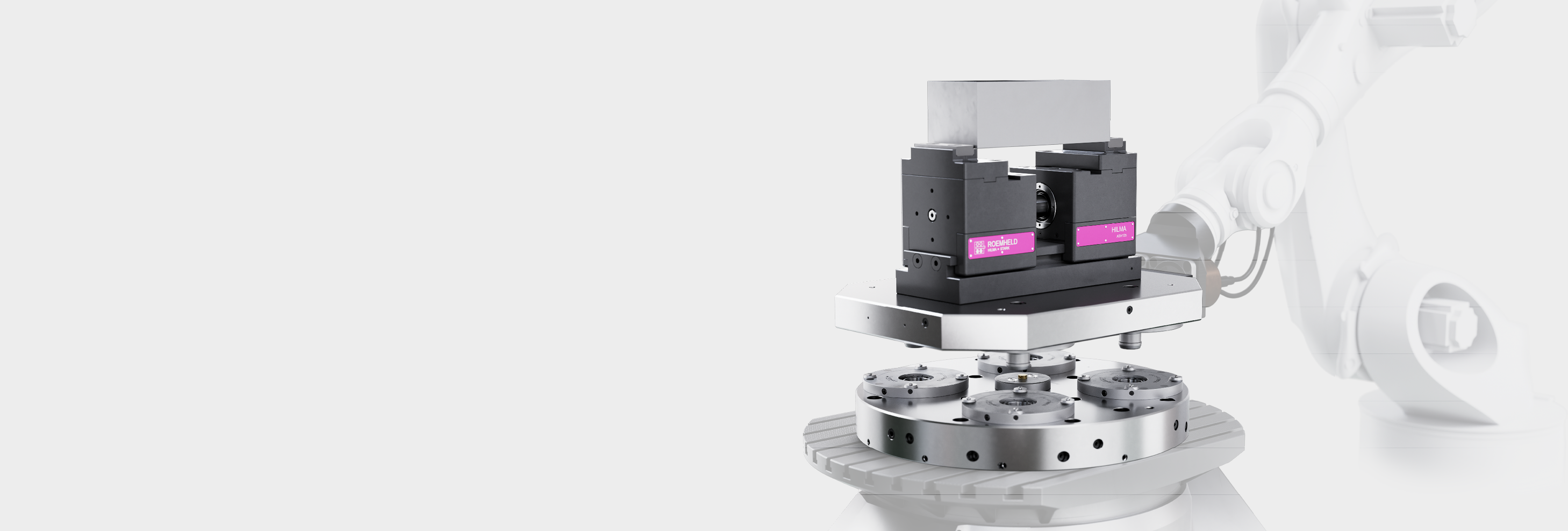

The fast closing clamps of the STARK.basic product family are zero point clamping systems with a wide range of applications. STARK.basic are used for installation in machine pallets, plates, angles, cubes, towers and swing bridges. Can be used for all common machining operations such as milling, turning, grinding, eroding as well as on test benches for assembly fixtures. The fast closing clamps made of high-quality tool steel are clamped mechanically and released pneumatically.

Special features of the STARK.basic product family

- Simple: modular design

- Economic: simple assembly and installation

- Price-conscious: cost effective entry-level models

- Compact: smallest STARK zero point clamping system

Benefits & Advantages

Design

- Compact design with high clamping forces and low installation depth

- Modular design

- Simple installation contour

- Easy to clean

- Easy to maintain - easy replacement

- Made of high-quality, stainless tool steel

- Internal piston seal

Space-saving, also on the pallet side

- The STARK.basic retractable nipple can be mounted easily

- Extremely space-saving installation form (for the STARK.basic.S, the retractable nipple protrudes only 15.5 mm)

- Easy handling of pallets due to short lifting paths

Slanted lifting out/in

- Workpieces, devices and pallets can be changed without tilting. Particularly important with asymmetrical weight distribution on the pallet

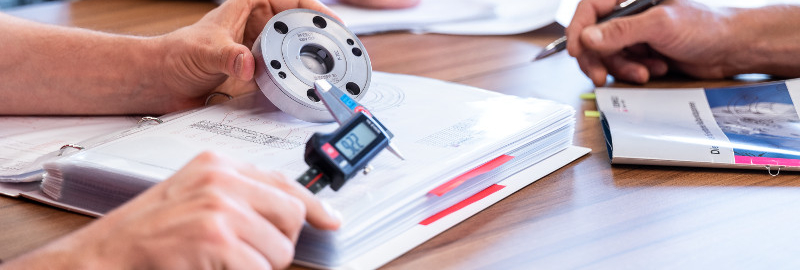

Positionally accurate up to the maximum load

- The spring force permanently fixes the retractable nipples precisely with positive locking

- Vibrations are damped, the quality of the surfaces to be machined is increased and the service life of the tools is extended

Intelligent blow-out technology

- Particularly effective cleaning due to the extending nozzle

- Suitable for partial automation and reduces cleaning effort

Positioning and clamping in one function

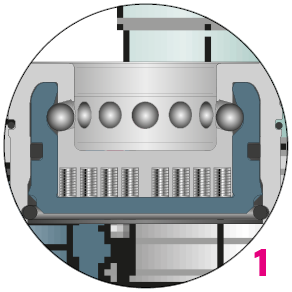

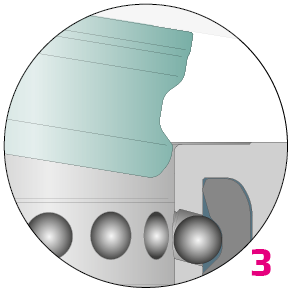

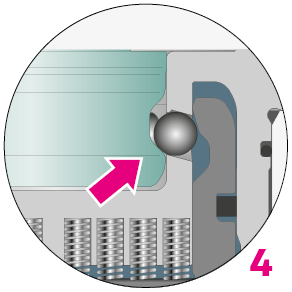

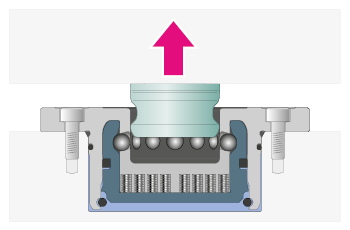

Release

- The piston (2) is subjected to the release pressure (1) and moves upwards.

- The springs (3) are pressed together.

- The balls (4) move to the parking position.

- The retractable nipple (5) is released.

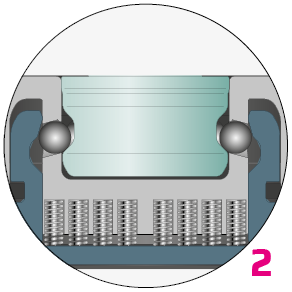

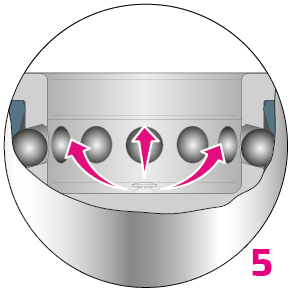

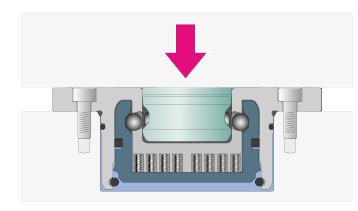

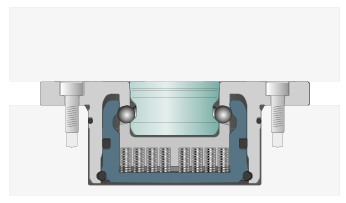

Clamp mechanically

- The pressure is relieved and drops to 0 bar.

- The spring pre-tensioning force is initiated via the piston (2) which moves down.

- The balls (4) are pressed inwards by the piston (2) and enclose the retractable nipple.

- The retractable nipple is securely clamped by the spring pre-tensioning force

Operating principle of the STARK.basic product family