STARK.classic.NG

Single acting, hydraulic or pneumatic

STARK.classic.NG clamping elements are clamped with spring force and released hydraulically or pneumatically. Both hydraulic-releasing and pneumatic-releasing clamping elements are designed with zero point. A third-hand function is possible with hydraulic-releasing clamping elements. STARK.classic.NG clamping elements are also available with indexing and/or coolant outlet.

Special features of the STARK.classic.NG product family:

- lifting: STARK.classic lifts the pallet upon release

- simple: easy to clean

- precise: due to cylindrical fit

- durable: press-fitted bolts

- versatile: clamping control, seat check, blow-out, media duct

Detailed information on the STARK.classic.NG product family can be found in the catalogue download:

Benefits & Advantages

The STARK.classic.NG product family consists of three sizes STARK.classic.NG.1, STARK.classic.NG.2 & STARK.classic.NG.3 and offers a wide range of features and benefits.

Benefits & Advantages

Tried and tested technology with system – original down to the smallest detail

1. Wear-resistant retracting and pre-centring

- Due to the special retractable nipple contour, the fitting diameter is not damaged when retracting in the clamping element.

- High alloy tool steel provides wear resistance.

2. Matched radii on the fitting diameter

- Matched radii on the clamping element and on the retractable nipple result in exact pre-positioning.

- The fit is joined by retracting the pallet. The operator only has to put down or remove the pallet.

- No chips can be trapped in the cylindrical bore.

3. Optimal force distribution — no bending or lifting

- Spring force permanently fixes the retractable nipples in a form-fit and highly precise manner. This has a vibration-damping effect and increases the quality of the surface to be processed as well as the service life of the tools.

- The spring force (F) acts in the immediate vicinity of the fixing screw (B). This means that there is no deflection on the disc (C).

4. Lifting out of the fit

- When releasing, the retractable nipple is lifted out of the fit in a controlled manner and the operator recognises that the system is released. This makes handling safe and extremely simple.

5. Inclined retracting and extending

- Changing workpieces, devices or pallets without tilting. Particularly suitable for asymmetrical weight distribution above the pallet with STARK.classic.NG.2 and NG.3.

6. Easy cleaning

- In machining production, contamination of the clamping system is unavoidable in the long term. Therefore, an easy cleaning option is very important.

- For the STARK.classic.NG fast closing clamp, the retaining ring (2), ball retainer (3) and spring (4) can be easily removed, cleaned and used again after the lock ring (1) has been removed. This enables easy maintenance and the lowest possible downtimes.

- Easy to exchange due to highly accurate tolerances – no need for set-up or tuning.

7. Precise support

- For special requirements, the Twister design can be supplied with a tolerance of 2 µ – particularly advantageous for high-precision, matched systems (e.g. clamping element changeover).

- Highest accuracy to reduce tolerance errors.

- The standard tolerance for the disc height of STARK clamping elements is 5 µ.

learn more

8. Integrated media duct

- For the passage of media such as oil, air, water, etc., STARK.classic.NG can be equipped with integrated media ducts (6) on request. These are automatically positioned and coupled during clamping.

- This allows, for example, clamping devices mounted on machine pallets to be supplied with energy (hydraulics, pneumatics, etc.). The coupling force is applied by the clamping element. With extremely simple handling, the pallet is positioned, clamped and coupled fully automatically.

learn more

9. Clamp control

- For safety reasons, a clamp control is strongly recommended for all high-speed applications. STARK.classic.NG can be optionally equipped with a mechanical clamp control valve (6) for this purpose.

- The evaluation of the clamp control can be integrated directly into the machine control system or can be displayed by means of a visual clamp control. Existing machines can also be retrofitted with a corresponding hydraulic unit and suitable control system.

learn more

10. HG – High-precision due to press fit

- High accuracy due to press fit between clamping element and retractable nipple.

- Used in high precision applications in 5-axis or rotary applications in the centre of the fast closing plate, e.g. turbine engine parts.

- This ensures that the axis of rotation is always precisely in the centre. This high accuracy ("aeronautical accuracy") is achieved by a press fit between the retractable nipple and the clamping element. The use of a press fit is made possible by the active insertion and lifting of the STARK.classic system.

learn more

Media ducts

Media ducts are used to feed media such as oil, air, water, etc. through the STARK.classic.NG zero point clamping system. This allows, for example, clamping fixtures mounted on machine pallets to be supplied with energy (hydraulic oil, compressed air). Media ducts each consist of two components: one for installation in the clamping element and one for installation in the pallet, which are automatically coupled when the retractable nipples are clamped.

Benefits

- Media ducts can be integrated directly into the STARK.classic.NG zero point clamping system.

- Up to 4 media ducts are possible per clamping element.

- The coupling travel is matched with the retraction path of the clamping elements.

Ways to increase precision

When the requirement must be more precise than precise!

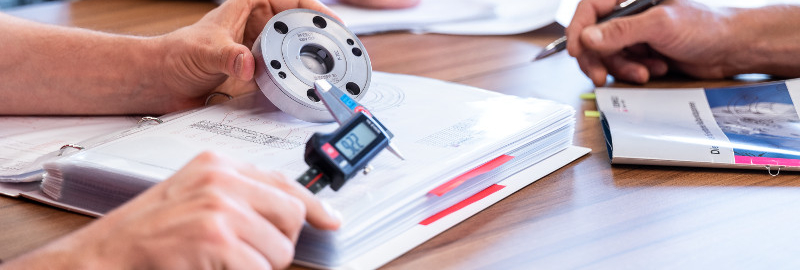

Our understanding of precision is the micrometre range: 1 µ corresponds to a thousandth of a millimetre and 5 µ is standard for us. With our in-depth and extensive industry know-how, we also offer opportunities to further increase accuracy in high-precision applications:

Shims to compensate for cumulative tolerances

2 µ accurate support discs - maximum accuracy even after changing clamping elements

HG versions - high-precision due to press fit

Shim – Equaliser options for cumulative tolerances

- Shims allow precise adjustment of the zero point clamping system (ZPC) in the Z plane.

- The shim is located between the fast closing plate (FCP) and the clamping element.

- After successful assembly of the fast closing plate, any height differences are determined. The shims can be ground according to the required tolerances. This procedure is repeated until the required tolerances are reached. This compensates for all cumulative tolerances of the machine, machine table and fast closing plate.

- Benefit

In case of service, a clamping element can simply be exchanged for another one, without time-consuming adjustment work. When changing the clamping element, the shim is not replaced. - Suitable for all clamping elements of the STARK.classic.NG product family.

2 µ – Precise support

The great advantage of the 2 µ version is that in the event of servicing a high-precision system, no height adjustment is necessary when replacing elements and machine availability is optimised.

- For special requirements, the Twister design can be provided with a tolerance of 2 µ: particularly advantageous for high-precision, matched systems (e.g. clamping element changeover).

- Highest accuracy to reduce tolerance errors.

- The standard tolerance for the disc height of STARK clamping elements is 5 µ.

HG – High-precision due to press fit

The STARK.classic.NG HG high-precision clamping elements ensure maximum precision when changing devices from the set-up station to the machine or from machine to machine. This maximum precision is achieved by using a press fit between the HG clamping element and the HG retractable nipple. The HG retractable nipple is joined or lifted by means of active insertion and lifting of the STARK.classic system. The materials and heat treatments selected for this highly demanding field of application ensure durable and wear-free operation.

- Used in high precision applications in 5-axis or rotary applications in the centre of the fast closing plate, e.g. turbine engine parts ("aeronautical accuracy").

- HG versions ensure that the axis of rotation is located in the centre with maximum precision.

Queries, blow-out & cleaning

In the STARK.classic.NG zero point clamping system, safety queries with pneumatic clamping and release control are possible. The access lines to the clamping elements are supplied pneumatically via deep-hole bores. This involves a dynamic pressure query. The seat check also works with dynamic pressure, but only serves as a precision check. Optionally, all elements are available with a third-hand function (THF). In addition to the query options integrated in the machine control system, the optical clamping control provides an option for clamping control independent of the machine. An intelligent blow-out and blow-off technology is used for cleaning the support islands and the fitting bore.

Clamping control

Optical clamping control

Released control

Seat check

Blow-out & Cleaning

Clamp control

Safety query

For safety reasons, a clamp control is strongly recommended for all high-speed applications. STARK.classic.NG clamping elements can be optionally equipped with a mechanical clamp control valve for this purpose. The evaluation of the clamp control can be integrated directly into the machine control system or can be displayed by means of a visual clamp control. Optionally, pressure boosters or hydraulic units with corresponding sensors can be connected to existing machines.

By using the mechanical clamp control valve (2), the correct and secure clamping of the fast closing clamp is checked during each clamping process. If clamping is not correct or without a retractable nipple, the piston moves beyond the normal position and blocks the flow of the hydraulic line (3) with the clamp control valve. On plates or in towers, all fast closing clamps are queried in series, so the exact clamping of all fast closing clamps can be checked at any time.

- Lock ring

- Clamp control valve

- Direction of flow

Optical clamping control

Is the zero point clamping system securely clamped?

In many applications, e.g. when turning, clamping control is mandatory. The optical clamping control shows the position of the piston after activation of the clamping control in the fast closing clamp and provides absolutely reliable information via a traffic light signal. Simple operation and easy retrofitting are key advantages with this safety component. The optical clamping control can be integrated into the fast closing plate.

Released control

Pneumatic release control is possible with standard elements of the STARK.classic.NG product family. The access lines to the clamping elements are supplied pneumatically via deep-hole bores. Here, the query can be realised via dynamic pressure / flow rate. The release control is recommended for applications with automation and heavy components.

Seat check

Precision testing

Pneumatic seat check is possible for standard elements of the STARK.classic.NG product family. The seat check works with dynamic pressure and is used for precision testing. The seat check is used to detect contamination between the pallet and the zero point clamping system.

Unlike the clamp control valve, the seat check is not a reliable safety feature. For safety-critical applications, clamp control is recommended.

Blow-out & Cleaning

Intelligent blow-out and blow-off technology for cleaning the support islands and the fitting bore. The blow-off takes place directly at the support surfaces and at the fitting diameter. To clean the support islands, air flows upward and mushroom-shaped downward via retractable nozzles.

- Island blow-off

- Centre blow-off

- Island blow-off

Nozzle functionality - Island blow-off

Nozzle retracted - Island blow-off

Nozzle extended - Openings for centre blow-off

Zero-point clamping systems

Minimum set-up time. Maximum reliability.

- maximum flexibility in production

- maximum process reliability

- reduced manufacturing costs thanks to set-up time optimisation

Functions

Single acting, hydraulic or pneumatic

STARK.classic.NG clamping elements are clamped with spring force and released hydraulically or pneumatically. Both hydraulic-releasing and pneumatic-releasing clamping elements are designed with zero point. A third-hand function is possible with hydraulic-releasing clamping elements. STARK.classic.NG clamping elements are also available with indexing and/or coolant outlet.

The pneumatic versions of the STARK.classic.NG product family are a useful addition to the hydraulic-releasing clamping elements. Particularly suitable for applications with low machining forces such as measuring machines, assembly applications or cleaning systems. For example, a device that has been clamped for machining with hydraulic-releasing clamping elements can be clamped easily and quickly for intermediate measurements or assembly work with pneumatic-releasing clamping elements.

Hydraulic or pneumatic release:

- The piston (2) is subjected to the pressure (1) and moves upwards. The spring assembly (3) is compressed.

- The balls (4) in the ball retainer (5) move outwards to the parking position.

- The retractable nipple (6) moves into the fast closing clamp until it rests against the piston crown.

- The retractable nipple (6) is pre-positioned.

Mechanical clamping:

- The system is relieved and the pressure drops to 0 bar.

- The spring pre-tensioning force is initiated via the piston (2) which moves down.

- The fit is joined and the retractable nipple (9) is positioned with high precision.

- The balls (8) lie form-fitted between the piston and the retractable nipple in the contour provided.

- The pre-tensioning force of the springs (7) now acts directly and permanently downwards on the retractable nipple.

Functional video

Zero point clamping system STARK.classic

Application examples

Application example - Milling machine

Typical application for milling machines

- Zero point clamping system STARK.classic.NG.2

- Clamp control valve per clamping element

- Visual clamp control

- Seat check

- Easy handling

System options and features

- Customer-specific spacing 300×200 mm

- Also suitable for direct workpiece clamping

- The clamp control safety feature can also be easily retrofitted thanks to the visual clamp control display

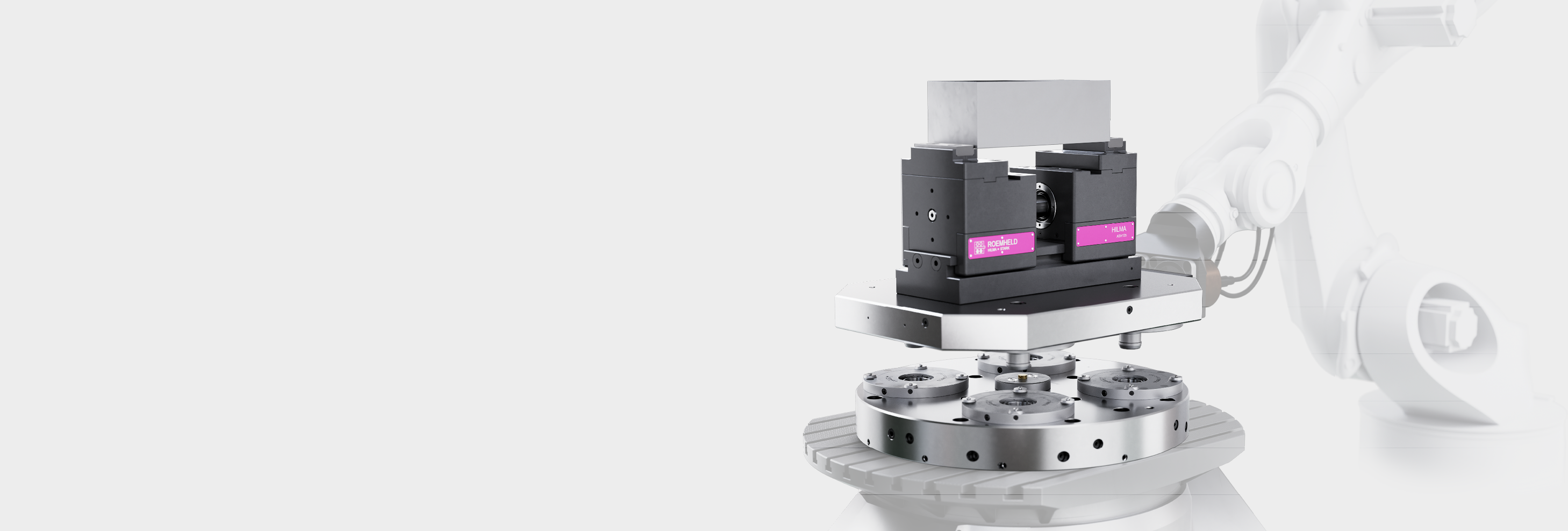

Application examples for STARK fast closing plate with HILMA vice

- Fast closing plate with 4 zero point clamping elements STARK.classic.NG.2

- Vice HILMA.NC 125

> Mechanically operated

> Clamping force display

- 2× pallet

- Vice HILMA.MCP 100 ZH

- Hydraulically operated

- Media duct

- 2× pallet

- Vice HILMA.MCP 100 FM

- Mechanically operated

Application example – Single application with STARK.classic.NG-S

STARK.classic.NG-S was specially developed for single clamping and 5-axis machining. This clamping element is ideal for manual and automated loading. A combination with the STARK.classic.NG clamping element is possible at any time. Versions with hydraulic and pneumatic actuation are available.

- For manual and automated loading

- Accurate to a µ

- Extremely high stiffness

- Form-fit is free of play due to spring-loaded pins

- Workpiece clamping via self-made adapter plates enables 5-sided accessibility

Application example – multiple coupling

Multiple couplings are used to control fixtures or hydraulic vices on machine pallets. Particularly suitable for automated loading due to integrated blow-out.

Typical application for milling machines

- Zero point clamping system with 4 STARK.classic.NG.2 Twister elements

- Multiple coupling with 4 connections

- Integrated blow-out

System options and features

- Customer-specific design

- 2 Pneumatic circuits for queries on the device

- 2 Hydraulic circuits for actuating the hydraulic device

Application example – Pre-centring

Pre-centring is used for easier and gentler loading of pallets and fixtures. Recommended for large or heavy components.

Grinding machine application

Aviation

- Zero point clamping system with 6 STARK.classic.NG.2 elements

- 3× pre-centring

- Centring elements with integrated media coupling

- Retractable nipple with spacer and support disc