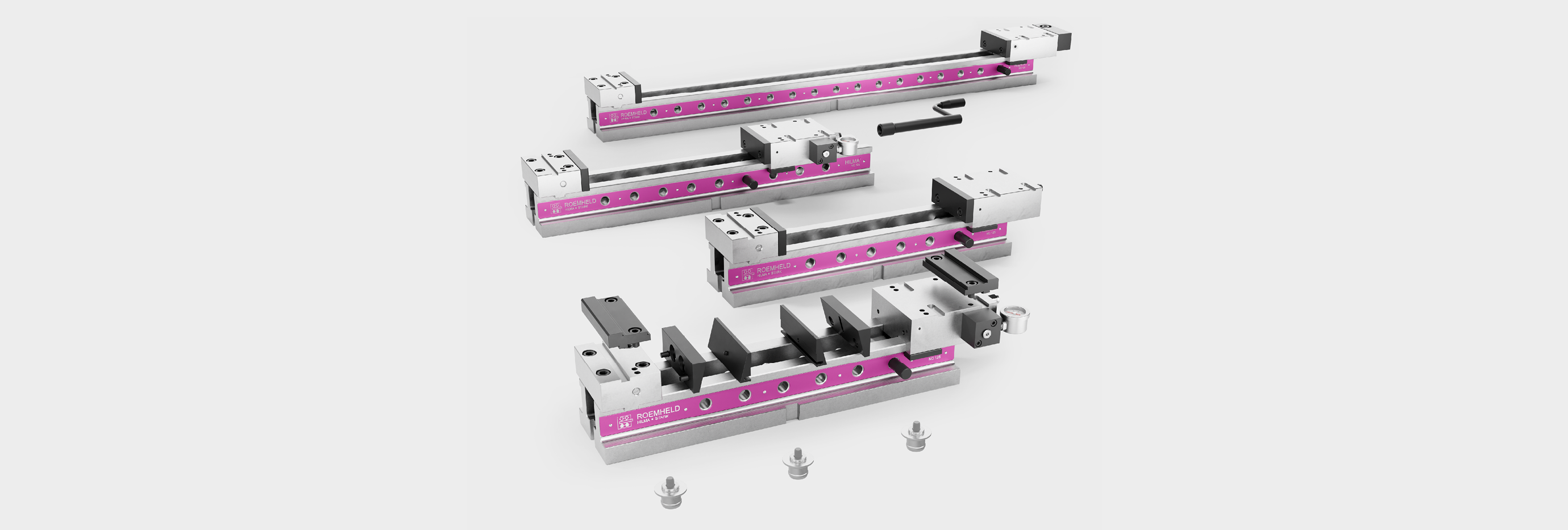

HILMA.UC machine vise

Concentric, modular, precise Jaw width 125 mm

The clamping system HILMA.UC is suitable for numerous clamping tasks and is used for machining dimensionally stable workpieces in single or multiple clamping systems.

Small workpieces as well as large plates can be clamped and machined without large interference contours. Even when production requirements change, there is no need to invest in new clamping devices.

Special features of the HILMA.UC machine vise family:

- universal modular system enables versatile clamping options

- stabile no deflection thanks to closed force flow

- compact reduced design ensures optimum accessibility

- Precise true to position due to pull-down mechanism

Detailed information on the HILMA.UC product family:

Maximum flexibility - 5-axis clamping system

The HILMA.UC machine vise

Advantages & Options

Flexible concentric clamping

High stability

-

Closed force flow - no bending force effect in the base - no deflection

-

Separation of adjusting and tension spindle - optimum force flow

-

Pull-down clamping jaws - active workpiece pull-down

Optimum accessibility

-

Compact design - good accessibility - optimum tool length can be used due to smallest interference contour

-

Raiser as accessory - improved accessibility for special clamping tasks

Concentric clamping system

-

Centre clamp, optimal for 5-axis applications

-

precise with repetitive accuracy

-

split mounting option

Flexible jaw opening & range of clamping jaws

-

Standard jaw opening from 0 - 200 mm, extension sets for extended jaw opening up to 600 mm

-

Conclusive range of clamping jaws for workpieces in all shapes and surfaces from round to square, small to large and smooth or uneven

-

Can be adapted to differently-sized workpiece geometries in just a few steps

Individual fastening

-

fastening with sliding block on T-slot table

-

fastening via clamping claws

-

fastening from above through the base by means of screws

-

quick change by means of STARK retractable nipple directly or via adapter plate in the STARK zero point clamping system

-

thread adapters for alternative zero point clamping system manufacturers

-

standard fast closing plates available

Flexible clamping widths

Extension sets for maximum jaw openings

The concentric clamping system can be divided in the middle and extended. The clamping range can be extended up to 600 mm by using different tension spindle/clamping nut combinations. A closed force flow is created between the tension spindle, adjustment element and clamping jaw, thus allowing the modular design. The base plate remains without a bending force being applied. The extended clamping system can be mounted directly on the machine table, raisers or adapter plates.

Standard Set 0 – 200mm

scope of delivery

Extension set 400

Extended clamping range

Extension set 600

Maximum clamping range

Fastening options

Options for fastening on the machine table

Stable Fastening on the machine table is of great importance to ensure precise machining. Fastening options can be selected depending on the type of processing and the individual requirements.

Direct mounting

- Direct mounting with Sliding block longitudinal on 5-axis T-slot table

Direct mounting with Sliding block crosswise on 3-axis T-slot table - Direct mounting with retractable nipples in the STARK zero point clamping system

- Direct mounting with screws from above on hole pattern

Direct mounting with screws from above on hole pattern with raiser on right image - Direct mounting in a 96 × 96 mm fast closing system

Adapter plate

- Fastening on adapter plate

- Fastening via adapter plate in zero point clamping system

- Fastening via adapter plate with clamping claws

- Fastening via adapter plate on hole pattern

Operating principle HILMA.UC

Clamping principle - closed force flow

1. Preset clamping range

The clamping range is preset until both clamping jaws are in contact with the workpiece without building up clamping force.

By turning the adjustment spindle clockwise, both adjustment elements move to the centre.

2. Mount tension spindle

The tension spindle is mounted hand-tight before the clamping force is applied by turning it clockwise using a torque wrench.

The force on the clamping jaws above the workpiece stop is introduced into the workpiece via the outer edges of the clamping claws.

The clamping force develops proportionally to the torque.

3. Clamping process

Most of the pulling force is applied directly to the workpiece. The adjustment spindles serve as counter bearings.

In the process, the adjustment elements are clamped to the base plate and the system is completely mechanically locked.

Due to the closed power flow from tension spindle to adjustment spindle, the base remains almost without bending force being applied and tilting of the adjustment elements is avoided.

Application examples

The jaws used have a major influence on the machining result. The range of clamping jaws enables reliable blank and finished part clamping in all shapes from round to square and from small to large.

For smooth clamping jaws and clamping jaws with GripPin, support bars are required as workpiece stops.

1. Pull-down clamping jaws

Suitable for clamping pre-machined or smooth surfaces (second side). The bending element of the jaw clamps the workpiece with pull-down and presses it onto the support surface with repetitive accuracy.

Clamping jaw 125 & 60 mm, smooth

For clamping pre-machined or smooth surfaces (second side). The clamping jaw has a clamping width of 125 mm. The narrow version of the clamping jaw has a clamping width of 60 mm and serves to optimise accessibility for narrow workpieces. The maximum clamping depth is 28 mm. Support bars are required for the clamping jaw.

Clamping jaw with GripPins 125 & 60 mm

For secure clamping of uneven surfaces such as saw cuts, blanks and cast parts. The clamping jaw has a clamping width of 125 mm, the maximum clamping depth is 28 mm. Attention: Marks of the pins on the workpiece.

4. Clamping jaws with round clamping bolts

Three-point clamping

For vertical clamping of cylindrical workpieces with a diameter of 30 bis 200 mm. The diameter can be flexibly adjusted by repositioning the inserts. Three- and four-point clamping can be realised. Attention: Clamping marks on the workpiece possible.

5. Clamping jaws with round clamping bolts

For vertical clamping of cylindrical workpieces with a diameter of 30 bis 200 mm. The diameter can be flexibly adjusted by repositioning the inserts. Three- and four-point clamping can be realised. Attention: Clamping marks on the workpiece possible.

6. Prism jaws

For clamping cylindrical workpieces with a diameter of 8 - 40 mm. Workpieces can be clamped horizontally or vertically. With vertical clamping it is possible to place two workpieces in the outer prisms at the same time. Support bars are optional for the clamping jaw.

Soft clamping jaws

Soft jaw for customer insertion of workpiece-specific clamping contours.

Support bars

The support bar creates a workpiece stop and at the same time determines the clamping depth for the workpiece. According to the desired clamping depth, the support bar can be aligned and inserted into the matching slot of the clamping jaw.

Detailed information

Articles of the HILMA.UC family on the Roemheld group page

Operation

Mounting

Set clamping range

Clamping jaws

Detailed information on the HILMA.UC product family can be found in the following downloads: