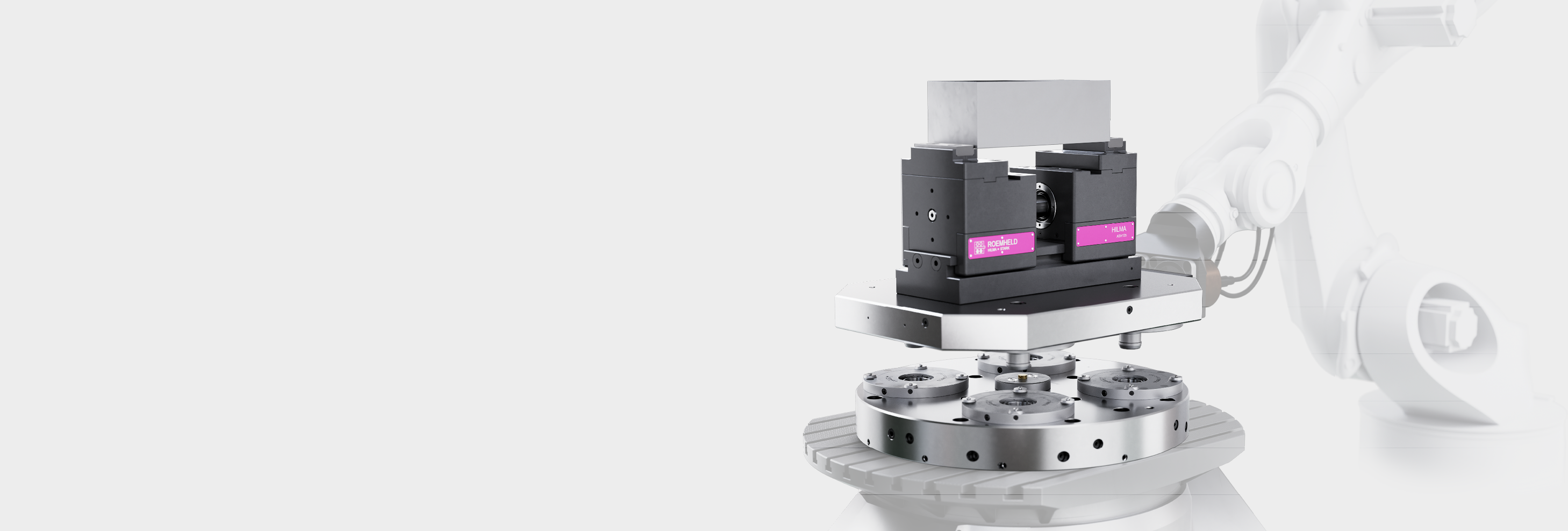

STARK.plaintec

Double-acting, hydraulic

The continuously adjustable clamping force makes possible optimal clamping. By adjusting the clamping pressure, unnecessarily high forces are not applied. As a result the receptacles or pallets do not need to be as strong, depending on the machining - the result is advantages in handling and price. A key aspect, e.g. during milling, is ensuring an adequate, but not excessively high clamping force during the machining to be able to absorb the machining forces. Clamping based on shape and force is ideal.

Maximum productivity

- With the STARK.plaintec you increase your production times to a maximum.

- This clamping element stands for the highest requirements in automation.

Maximum flexibility

- STARK.plaintec has a uniform interface that can be arranged in variable ways.

- STARK.plaintec features a compact design, easy assembly as well as fast changing cycles.

Maximum safety

- Double-action zero point clamping system with small size and high clamping force.

- Easy handling, as the pallet can be moved to the clamping element with practically no lifting.

Special features of the STARK.plaintec product family:

- unique: flush-mounted fast closing

- clamp and clamping spigot

- sliding: handling without interfering contours

- very strong: 50 kN retention force

- independent: suitable for automation

- monitored: all functions can be monitored

Positioning and clamping in one function

- Move to STARK.plaintec:

Simple positioning of the pallet with radial pre-centring of ±0.4mm. - STARK.plaintec clamped:

The piston is pressed up and during this process positions the pallet precisely. The inner piston follows (sequential control), the ball chain clamps the clamping spigot with its shape. The clamping pressure is now applied to the system. - Release STARK.plaintec:

On releasing the inner piston moves down, the ball chain releases the clamping spigot, then the outer piston is lowered and the pallet released.