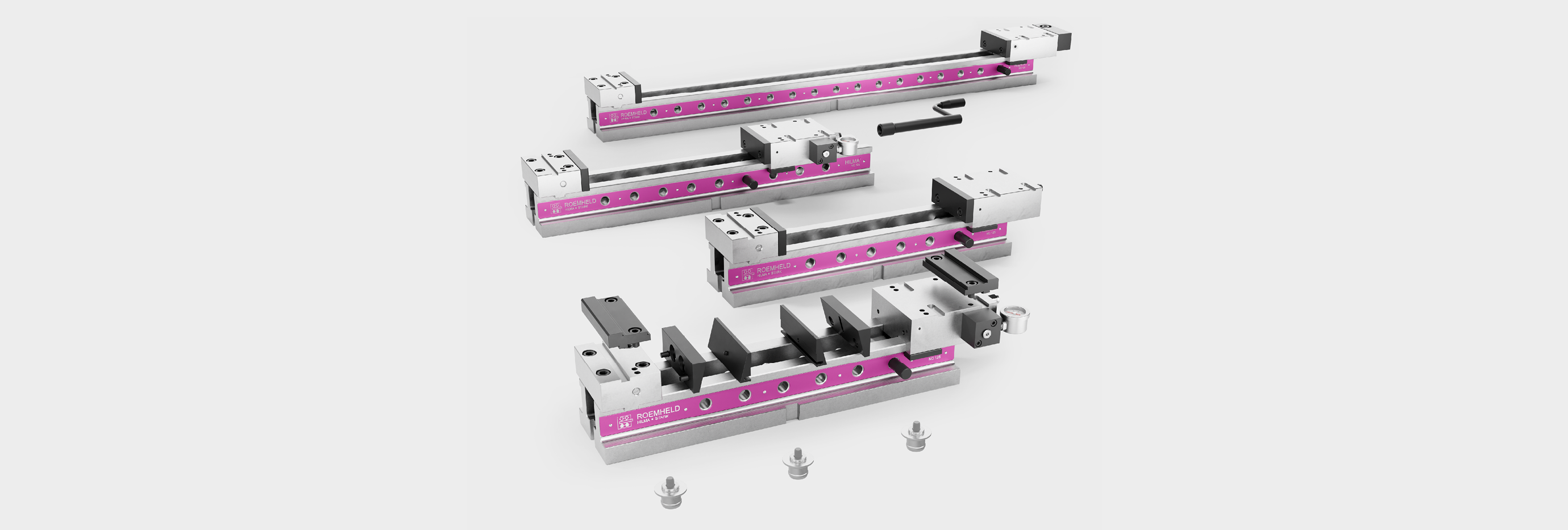

HILMA.NC machine vise

jaw widths 100, 125 and 160 mm

The modular system of the HILMA.NC series is preferably used on vertical machining centres. Depending on the machining strategy and degree of automation, the clamping force can be applied manually by means of a crank handle (HILMA.NC) or hydraulically by means of a power unit (HILMA.NCH).

Special features of the HILMA.NC machine vise family:

- adapted: three jaw widths and variable base lengths

- modular: extensive range of jaws and accessories

- fixed: optimal possibilities for fixation

- safe: precise and constant clamping force

- clean: easy cleaning

Detailed information on the HILMA.NC product family:

The variable basis

HILMA.NC machine vise

Depending on the machining strategy and degree of automation, the clamping force can be applied manually by means of a crank handle (HILMA.NC) or hydraulically by means of a power unit (HILMA.NCH). Different jaw widths & variable base lengths ensure optimum adaptation to the existing circumstances such as machining task, machine & environment. The extensive range of jaws rounds off the flexible clamping system. The base of the vise can be fixed to the machine table by means of a zero point clamping system, clamping claws or screws and pins. Optional rework on the base of the machine vise allows additional positioning and fixation options.

Series & Operation options

The HILMA.NC mechanical/hydraulic machine vise is designed for tool, mould and fixture construction as well as for production and is suitable for small to medium batch sizes.

The HILMA.NCH hydraulic machine vise is designed for use in semi-automated operation and series production and is preferably used on vertical machining centres. The hydraulic series has advantages for medium to large batch sizes with short machining cycles.

HILMA.NC

Mechanically operated machine vise

- Manually by means of crank handle and hydraulic force transmission

- Linear, continuously variable force build-up by means of a crank handle

- No external pressure generator necessary

- Hydraulic slides can be retrofitted

HILMA.NCH

Hydraulically operated, single-acting machine vise

- Single-acting

- Connection to power unit or machine hydraulics

- Hydraulically using a power unit, e.g. by means of a hand/foot switch, Machine-controlled

- Semi-automated processes, improved ergonomics, short clamping and release times

- 5 mm stroke for jaw widths 100, 125

7 mm stroke for jaw width 160

Series & Options

Jaw widths & base lengths

- Three jaw widths 100, 125 and 160 mm

- Up to five standard lengths per jaw width from 380 to 1200 mm

- Optimum adaptation of the clamping system to the machine and clamping task

- Individual desired lengths up to 1200 mm possible

Fixation, positioning & quick change

- Fixation using lateral clamping claws

- Fixation from above through the base by means of screws and pins

- Quick change by means of retractable nipple directly or using adapter plate in the zero point clamping system

- Customised fixation and positioning bore holes in the base of the vise at the factory according to parameter specifications or as rework possible

Socket pin

Pulling out the socket pin allows the clamping slide to move freely:

- A coarse adjustment of the clamping range

- Quick slide adjustment, without prolonged actuation of the crank handle

- Easy removal of the clamping slide

- Without clamping slide, the base can be cleaned easily and quickly

- Easy to service

Additional options - Flat rate reworking

The standard base of the HILMA.NC series can be adapted to specific machine requirements through various rework operations. The standardised additional options are offered at an attractive flat rate price.

Additional slot for displaceable fixed ja

Optionally, the fixed jaw can be adjusted by means of an additional slot in the slide guide surface. The adjustable fixed jaw enables operator-friendly set-up for workpieces of different sizes. Recommended for ergonomic operation with large base lengths and smaller clamping ranges.

Additional crosswise keyway for Positioning

An additional crosswise keyway is used for optimum positioning on the machine table. The position of the additional crosswise keyway can be freely selected after consultation and verification of feasibility.

Additional threaded fastening holes & retractable nipple bore holes

Customised threaded fastening holes and positioning bore holes in the base of the vise at the factory according to parameter specifications or as reworking are possible.

Customised designs - Base of vise according to customer requirements

In addition to the standard versions of the modular HILMA.NC series, customised base versions can be realised. This means that the machine vise can be manufactured to fit precisely for individual travel paths, working spaces, clamping surfaces and machining tasks.

Possible options and designs include:

- Freely selectable intermediate lengths

- Segment design

- Fixed jaws - & clamping segment

- Multiple clamps

- Larger heights

- Own spacing for retractable nipple

Freely selectable base intermediate lengths

Example option

In addition to the standard versions of the modular HILMA.NC series, customised base versions can be realised. This means that the machine vise can be manufactured to fit precisely for individual travel paths, working spaces, clamping surfaces and machining tasks. Possible options and designs include: In addition to the standard lengths, customised intermediate lengths can be ordered. The length of the base of the vise can be designed as desired up to the largest standard length of the respective jaw width.

Segmental design

Example option

The segments can be placed anywhere on the machine table and are mainly used on large machining centres. Large working spaces can be optimally used with standard clamping systems and complex devices for workpiece clamping are no longer required.

Multiple clamps

Example option

Flexible dual clamping systems enable the efficient double machining of workpieces with the same or different dimensions. Both clamping locations work independently of each other.

Mounting versions

Options for fixaxtion on the machine table

Stable fixation on the machine table is of great importance to ensure precise machining. Depending on the type of machining and the individual requirements, one of the fixation options shown below can be selected.

- Screw connection

- Clamping device such as clamping claws

- Zero point clamping system

Function & advantages

HILMA.NC and HILMA.NCH

Depending on the machining strategy and degree of automation, the clamping force can be applied manually by means of a crank handle (HILMA.NC) or hydraulically by means of a power unit (HILMA.NCH).

Function HILMA.NC

Hydraulic force transmission for mechanical operation

1. coarse adjustment

- By pulling out the socket pin, the clamping slide can be moved freely and allows a coarse adjustment of the clamping range.

2. fine adjusted

- The workpiece is finely adjusted manually using a threaded spindle (crank handle By turning the threaded spindle clockwise, the slide is mechanically fed to the component. Clamping is not yet established.

3. clamping force build-up

- After a noticeable resistance (disengagement of the index bolt), the hydraulic clamping force builds up (linearly up to the maximum) and ensures a tight fit of the workpiece. Cranking requires little effort due to the hydraulic clamping force build-up.

- Release: By turning the crank handle anti-clockwise until the the index bolt engages causes a continuous reduction of the clamping force. When turning further, the machine vise is opened.

Clamping force display

HILMA.NC

- Continuous display of the clamping force

- Continuous and exact application of the clamping force

- When using clamping jaws with a coating or grip serration, controlled clamping is only possible in conjunction with a clamping force display

- Optimisation of operation through precise reproducibility of the clamping force

- No deformation of the workpieces due to exact application of the clamping force

- High process reliability - continuous clamping force display

- Roughing and finishing in one arrangement

Clamping force preselection

HILMA.NC

- Mechanical limitation of the clamping force build-up to a fixed value in 6 steps

- reduces the deformation of the components and reduces operating errors

Angle drive

HILMA.NC

The alternative actuation option using the angle drive with crank handle enables ergonomic operation when access is difficult.

- Recommended from a base length of 540 mm

- Retrofittable

Function HILMA.NCH

Hydraulically operated, single-acting

1. coarse adjustment

- By pulling out the socket pin, the clamping slide can be moved freely and allows a coarse adjustment of the clamping range.

2. fine adjustment

- Fine adjustment up to the hydraulic stroke is achieved by means of a crank handle. By turning the threaded spindle clockwise, the slide is mechanically fed. Clamping is not yet established.

3. fine adjustment

- Actuation is achieved using an external pressure generator. This can be the machine hydraulics or a separate power unit. By switching on the hydraulics, the clamping force is built up according to the preadjusted operating pressure (bar).

- (a) Hydraulic connection left or right / Bleeding screw left or right

- (b) Insertion position: Hydraulic Stroke 5 - 7 mm

Semi-automated workpiece change in series production

HILMA.NCH

The semi-automatic workpiece change in production enables fast, efficient and safe handling of workpieces, resulting in higher productivity and quality. Several clamping locations on a machine table can be actuated simultaneously via a trigger - with process reliability and repeat accuracy. Actuation by means of the foot switch enables two-handed loading and unloading of large-volume or heavy workpieces.

- Improved working conditions and ergonomics: the operator's workload is reduced

- Efficient production: increased throughput, time and cost savings, minimised downtime

- Flexible production: quick changes between different workpieces

- Higher product quality due to semi-automated handling

Clamping force / clamping pressure

HILMA.NCH

The clamping force is set on the hydraulic unit via the hydraulic pressure

- The clamping force is applied with repeat accuracy, operating errors are minimised

- Increased process reliability - the clamping force is monitored on the power unit and corrected if the clamping situation eases of

Detailed information

Articles of the HILMA.NC family on the Roemheld group page

Application examples

The clamping force is set on the hydraulic unit via the hydraulic pressure. The jaws used have a major influence on the machining result. The extensive range of jaws enables reliable blank and finished part clamping in all shapes from round to square and from small to large. All jaws are hardened on the reference surfaces and ground with high precision (except soft clamping jaw).

1. Jaws with interchangeable insert

Standard reversible clamping jaw with one side ground smooth for clamping finished parts and one side serrated for clamping blanks.

2. Claw jaws with fine grade

For blank clamping. A clamping depth of 2.5 mm (pull-down effect) results in little material loss on the workpiece. 5 sides can be machined in a single clamping operation without pre-stamping.

3. Top jaw segments

Top jaws are used for clamping large workpieces. They are used in pairs on slides and fixed jaws.

4. SlimFlex - with step inserts

The SlimFlex jaw system allows 3-sided machining of centrally clamped workpieces that are dimensionally below the jaw width of the clamping device.

5. Top jaws

Top jaws are used for clamping large workpieces. They are used in pairs on slides and fixed jaws.

6. PinFlex clamping jaws

The use of PinFlex clamping jaws allows fast and precise alignment of workpieces. This is supported by horizontal and vertical scaling.

7. Jaws with interchangeable insert

The clamping jaws can be used for blank and finished part clamping due to the interchangeable insert.

8. Pendulum jaws

Pendulum jaws are used to compensate angular errors on the workpiece (max. swivel range 5°). They enable the safe clamping of sawn sections, for example, in a simple way.

9. Top jaw segments

Top jaw segments are used for clamping round blanks, for example. A clamping force display is recommended. They are used in pairs on slides and fixed jaws.

10. Vee jaws

Cylindrical parts - vertical

11. Vee jaws

Cylindrical parts - horizontal

12. QIS quick-change jaws

The base jaws of the QIS system are equipped with permanent magnets and are screwed to the fixed jaw or slide. The QIS interchangeable jaws can be easily and quickly attached to the QIS base jaws without tools.

Clamping jaws

The clamping jaws of the HILMA.NC machine vises are designed as exchangeable clamping bars. Using clamping jaws or jaw inserts with coating or grip serrated, the retention forces for safe clamping of workpieces can be considerably increased.

- The HILMA.NC and HILMA.NCH series are delivered with smooth/serrated clamping jaws.

- When using inserts or clamping jaws with a coating or grip serration, controlled clamping is only possible in conjunction with a clamping force display.

PinFlex clamping jaws

The use of PinFlex clamping jaws allows fast and precise alignment of workpieces. This is supported by horizontal and vertical scaling.

- Workpiece support steps

- Clamping depths

- Angle, contours

- Workpiece stop

Dropping workpiece supports and disturbing workpiece stops are no longer required.

Function:

The pins are extended in rows with the aid of compressed air (e.g. compressed air gun) and pushed back individually depending on the application.

SlimFlex jaw system

Optimised 3-sided machining of workpieces in one clamping operation

The SlimFlex jaw system allows 3-sided machining of centrally clamped workpieces that are dimensionally below the jaw width of the clamping device. Due to the step inserts, the workpiece is free to move against the base jaws and thus make it optimally accessible for the work spindle from 3 sides.

- No asymmetrical loading of the workpiece

- Simple adjustment of different jaw widths

Top jaws

Top jaws are used for clamping large workpieces. Top jaws are a simple and effective way to extend the jaw opening. They are used in pairs on slides and fixed jaws. Used for clamping pre-machined or finished workpieces.

- S1: Clamping range for lower step of top jaw

- S2: Clamping range for upper step of top jaw

- S3: Clamping range for lower step of top jaw

- S4: Clamping range for upper step of top jaw

- h2: Distance dimension between guideway and lower step of top jaw

- h3: Distance dimension between guideway and upper step of top jaw

QIS quick-change jaws

Jaw change in seconds with magnetic QIS jaws (Quick Insert System).

The base jaws of the QIS system are equipped with permanent magnets and are screwed to the fixed jaw or slide.

The QIS interchangeable jaws can be easily and quickly attached to the QIS base jaws without tools.

Operating principle of the quick-change jaws:

- Mount the magnetic base jaw

- Introduce QIS interchangeable jaw in parallel & guide alignment pin

- Push the QIS interchangeable jaw up to the end of the slot and tilt

Detailed information on the HILMA.NC product family can be found in the following downloads: