STARK.balance

Single acting, hydraulic

The STARK.balance fast closing clamp is a hydraulic single-acting zero point clamping system. A piston is held in the clamping position by springs. The clamping mechanism can be moved in the X and Y axis with little force. The STARK.balance.2 zero point clamping system is available in Standard, Twister and Direct Clamping versions. Optionally, each element is available with a third-hand function (THF). The following list shows the function and query options of the different versions.

Special features of the STARK.balance product family:

- Equalising: Equalisation up to ± 0.75 mm

- Monitored: all functions can be queried

- Direct: designed for direct workpiece clamping

- Lifting capability: STARK.balance lifts pallets when released

- Optimal: best suited for large devices

Detailed information on the STARK.balance product family can be found in the catalogue download:

Benefits & Advantages

Tried and tested technology with system – original down to the smallest detail

1. Balance function

- Compared to a classic zero point clamping system, the STARK.balance fast closing clamp offers a greater equalisation of ± 0.75 mm.

- Specially developed to meet the special requirements of direct clamping and large pallets.

learn more

2. Pre-tensioned force & active insertion

- Maximum catch range with 1 mm travel for STARK.balance.2

- The spring pre-tensioning force is initiated via the piston which moves down. The fit is joined and the retractable nipple is positioned with high precision.

- Media feedthroughs are coupled by the active insertion or decoupled by the lifting.

3. Query

- Safety queries with pneumatic clamping and release control are possible as standard. The access lines to the clamping elements are supplied pneumatically via deep-hole bores.

- Clamping control, release control and seat check.

- Third-hand function position query.

learn more

4. Direct clamping

- Thanks to an integrated equaliser function in the STARK.balance fast closing clamp, the workpiece can be clamped directly in the thread without any additional effort.

- Existing threads on the workpiece can be used. A fit is not required.

learn more

5. Ease of service

- In machining production, contamination of the clamping system is unavoidable in the long term. Therefore, an easy cleaning option is very important.

- For the STARK.balance fast closing clamp, the retaining ring, ball retainer and spring of can be easily removed, cleaned and reinserted after removing the locking ring. This enables easy maintenance and the lowest possible downtimes.

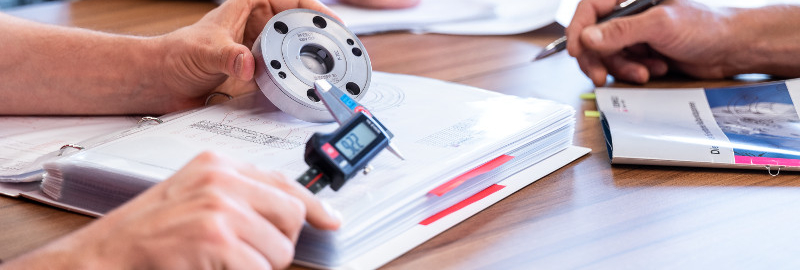

- Easy to exchange due to highly accurate tolerances – no need for set-up or tuning.

6. Wear-resistant insertion & pre-centering

- Due to the special retractable nipple contour, no damage occurs to the fitting diameter when inserting into the STARK.balance fast closing clamp.

- High alloy tool steel provides wear resistance.

7. Third-hand function (THF)

The third hand function (THF) engages the workpiece or pallet in the zero point clamping system. Once the pallet or workpiece is engaged on all sides, it is secured against falling out and the clamping process can be completed easily and safely.

8. Blow-out & cleaning

Intelligent blow-out and blow-off technology for cleaning the support islands and the fitting bore. The blow-off takes place directly at the support surfaces and at the fitting diameter. To clean the

support islands, air flows upward and mushroom-shaped downward via retractable nozzles.

9. Lifting from fit

When releasing, the retractable nipple is lifted out of the fit in a controlled manner and the operator sees that the system is released. This makes handling safe and extremely simple. Controlled movement in and out of the fit minimises wear on the fit.

10. Optimal force progression

- High positioning accuracy due to optimum force flow – no bending or lifting.

- Systems with active insertion ensure stable force transmission – the force is transmitted from the workpiece via the retractable nipple into the element and via the element housing further into the machine table.

- Spring force permanently pulls the retractable nipples into the system in a form-fit and highly precise manner – this has a vibration-damping effect and increases the quality of the surface to be processed as well as the service life of the tools.

balance function

Zero point accuracy with equaliser

The STARK.balance fast closing clamp offers a very large equalisation of ± 0.75 mm and has been specially developed to meet the special requirements for direct clamping and large pallets.

Functional principle

- During the clamping process, the retractable nipple moves into the fast closing clamp until it rests against the piston crown.

- The clamping mechanism (1) & (2) can equalise for position deviations from the retractable nipple to the element with little force.

- For the equaliser element in one axis and for the element without centring in the X and Y axis (± 0.75 mm).

Equalisation via fast clamping clamp

Area of application

- Different materials between pallet and plate

- Pallets with the same retractable nipple

- For a large number of pallets

- Direct tool clamping

- Tolerance range ± 0.75 mm

Low production costs

For large centre distances, the advantage of a large equalisation can lead to much cheaper manufacture and thus significant cost savings. There are no processing steps, which also reduces the

cycle time for the manufacturing of fast closing plates and pallets.

Thermal expansion

Temperature changes, e.g. night 17 °C / day 32 °C, require special precautions to prevent redundant dimensioning (e.g. in the case of aluminium, this change in temperature modifies a centre distance

from 1000 mm to 1000.36 mm).

Manufacturing tolerances

Due to the large equalisation, it is sufficient to prepare the position of the elements and retractable nipples with generous tolerances. The entire system is always zero point accurate.

You determine the zero point.

Zero point and axis alignment are retained and are always known. A total of up to ± 0.75 mm can be compensated.

Direct clamping

Clamping directly on thread

STARK has developed the STARK.balance product families for the special requirements for direct workpiece clamping.

The STARK.balance series has special advantages: existing threads on the workpiece can be used. A special fit is not required. Thanks to an integrated equaliser function in the clamping element ± 0.75 mm, the workpiece can be clamped directly in the thread without any additional effort.

The retractable nipples are available with different threads. They can be screwed in either manually or automatically. The system is zero point accurate and therefore the workpiece can be used across several machines or for intermediate measurements.

Example requirements

- Workpiece processing with zero point accuracy across multiple machines

- 5-side accessibility

- Use existing threads on the workpiece

- Zero point oriented flexibility

- Equaliser options for tolerances and temperature variation

- Predestined for castings

Query

In the STARK.balance.2 zero point clamping system, safety queries with pneumatic clamping and release control are possible as standard. The access lines to the clamping elements are supplied pneumatically via deep-hole bores. This involves a dynamic pressure query. The seat check also works with dynamic pressure, but only serves as a precision check. Optionally, all elements are available with a third-hand function (THF). In addition to the query options integrated in the machine control system, the optical clamping control provides an option for clamping control independent of the machine.

System internal queries

Dynamic pressure is generated by the piston position

- Release control

Perfect for automation and heavy components - Clamping control

Safety query - Third-hand function (THF)

Status query for safe handling

Query outside the element

Dynamic pressure is generated by the workpiece system

- Seat check

Precision check

Optical clamping control

Is the zero point clamping system securely clamped?

In many applications, e.g. when turning, clamping control is mandatory. The optical clamping control shows the position of the piston after activation of the clamping control in the fast closing clamp

and provides absolutely reliable information via a traffic light signal. Simple operation and easy retrofitting are key advantages with this safety component. The optical clamping control can be integrated into the fast closing plate.

Blow-off & cleaning functional principle

Intelligent blow-out and blow-off technology for cleaning the support islands and the fitting bore. The blow-off takes place directly at the support surfaces and at the fitting diameter. To clean the support islands, air flows upward and mushroom-shaped downward via retractable nozzles.

- Island blow-off

- Centre blow-off

- Island blow-off

Nozzle functionality - Island blow-off

Nozzle retracted - Island blow-off

Nozzle extended - Openings for centre blow-off

Functions

Single acting, hydraulic

The STARK.balance fast closing clamp is a hydraulic single-acting zero point clamping system.

A piston is held in the clamping position by springs. The clamping mechanism can be moved in the X and Y axis with little force.

Release hydraulically:

- The piston (2) is subjected to the hydraulic pressure (1) and moves upwards. The spring assembly (3) is compressed.

- The balls in the ball retainer (4) move outwards to the parking position.

- The retractable nipple (5) moves into the fast closing clamp until it rests against the piston crown.

- The clamping mechanism can equalise for position deviations from the retractable nipple to the element with little force. For the equaliser element in one axis and for the element without centring in the X and Y axis (± 0.75 mm).

- The retractable nipple (5) is pre-positioned.

Clamp mechanically:

- The hydraulics are released. The hydraulic pressure drops to 0 bar.

- The spring pre-tensioning force is initiated via the piston (6), the piston moves down and grips the retractable nipple. The fit is joined and the retractable nipple (7) is positioned with high precision.

- The zero point element positions in both axes and the equaliser element ensures a completely defined system by positioning in one axis.

- The balls (8) lie form-fitted between the piston and the retractable nipple in the contour provided.

- The force of the springs (9) now acts directly and permanently on the retractable nipple and pulls it down into the system.

Productvideo

STARK.balance - flexible solution for workpiece direct clamping

Functional video

Zero point clamping system STARK.balance

Application examples

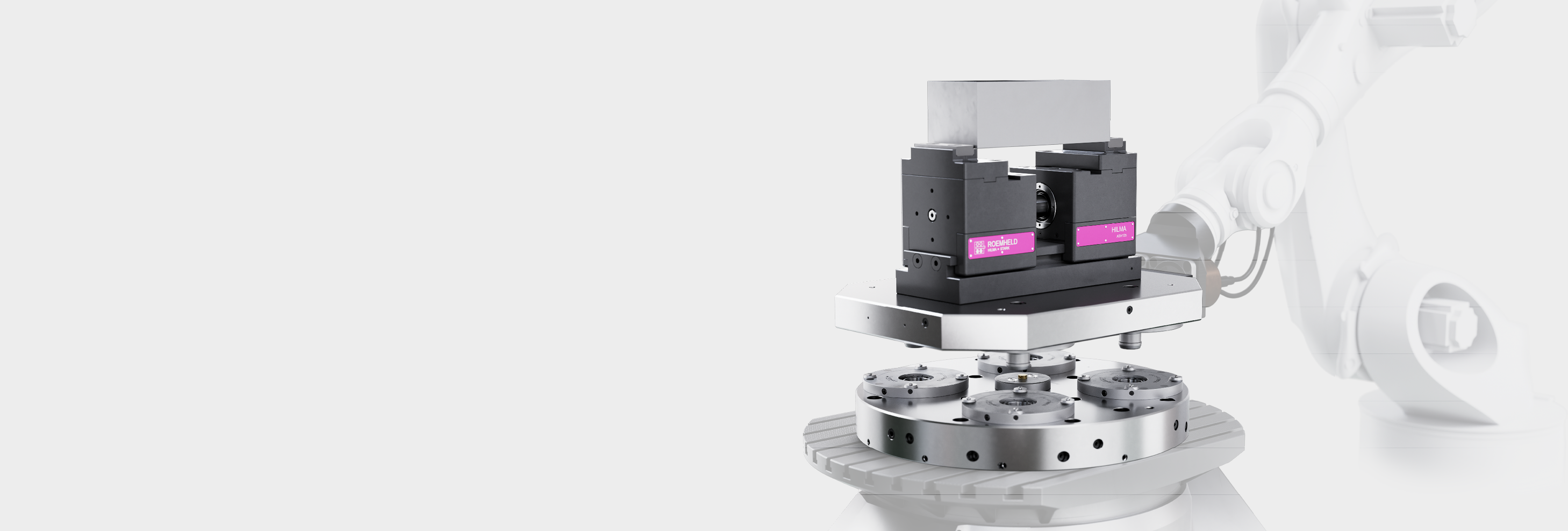

Application example – turning machines

Direct workpiece clamping for turning machines

- Zero point clamping system with 4 STARK.balance elements (S801-20x)

- Optical clamping control

- Asymmetrical arrangement of elements – position orientation

- 5 ½ sides accessible for processing

- Simple conversion – clamped in jaw chuck, secured with screws

System options

- Elements with third-hand function

- Clamping control – via the machine control system or optical clamping control

- Seat check possible

- Direct assembly on spindle nose possible

- Control via rotary transmission possible

Application example – milling machines

Typical application for milling machines

- Zero point clamping system with 4 STARK.balance elements (S801-20x)

- Optical clamping control

- Flattened STARK.balance for narrower centre distance

- Raised or bevelled fast closing plate for optimal 5-axis processing

- 5 sides with unrestricted access

System options

- Elements with third-hand function

- Clamping control – via the machine control system or optical clamping control

- Seat check possible

- Adapted fast closing plate and elements for optimum customer benefit